Company Information

Ask for more detail from the seller

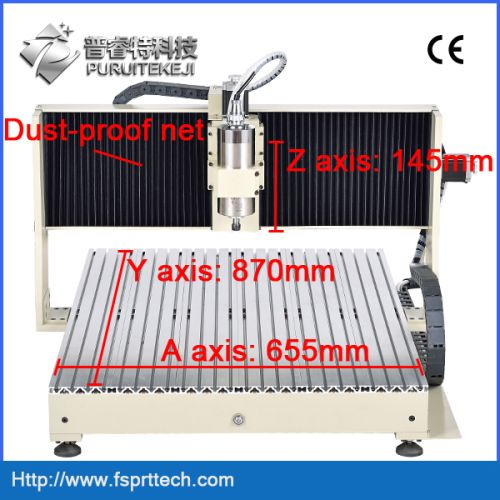

Contact SupplierMachine dimension: 1150*975*650mm(l*w*h)

workbench dimension: 1045*720*150mm(l*w*t)

frame material: full kit with 6061 aluminum processing

effecting cutting: x axis: 655mm, y axis: 870mm, z axis: 145mm

maximum thickness of workpiece: ≤165mm(gap between workbench and the bottom of z axis)

slide unit: x axis: φ20 high-intensity circular orbit, y axis: sbr20 high-intensity lead rail of aluminum base, z axis: φ12 high-intensity circular orbit

drive unit: x axis: sfu1605 ball screw, y axis: sfu1605 ball screw, z axis: sfu1204 ball screw

stepper motor: 57 mode, 3a two-phase stepping motor (come with handwheel)

stepper motor drive: 0~3.5a 4 axis driver can be adjusted(tb6560ahq chip, 24v

power supply, 2,4,8 and 16 segment can be set, factory reset: 8 segment)

stepper motor drive power supply: ac110-220v, 240w, output: dc24v10a

max air line speed: 1500mm per min

cutting speed: 50-1500mm per min(set corresponding speed according different materials)

standard spindle: 2200w high-speed converter spindle, er11 collet, 6mm core

rotate speed: 0-24000rmin

repositioning resolution: ≤0.05mm

spindle accuracy: circular runout≤0.03mm

cooling method: water cooling, equipped with cooling submersible pump

converter: av220v, 1500w, 0-400hz(built-in control box)

carving instruction: g codetab filenc filencc file

acceptable software: mach3, emc2

electric protection: emergency stop button

communication interface: parallel port to computer

software environment: windows xp 32 bite, windows7 32 bite

input voltage: ac220v(custom-made ac110v)

bare engraver net weight: 92.5kg

full kit gross weight: 105.3kg(including package).