Company Information

Ask for more detail from the seller

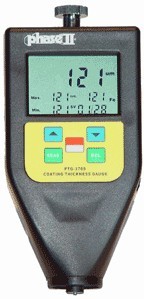

Contact SupplierThe new! phase ii ptg-3700 coating thickness gaugepaint thickness gauge is the latest, state-of-the-art thickness gauge in which you can easily detect the thickness of non-magnetic coatings on magnetic(ferrous) substrates or an insulating coating on a non-magnetic conductive substrate(non-ferrous). The ptg-3700 coating thickness gauge utilizes an integrated auto-detect probe, while the ptg-3750 coating thickness gauges uses an external probe.

the auto detect probes on these coating thickness gaugespaint thickness gauges use both eddy current and magnetic induction technologies.

the ptg-3700 series coating thickness gaugespaint thickness gauges are full featured w giant screen, backlighting, wider measuring range, advanced memory, browsing and statistics, such as minmax values, averaging and counters.

the ptg-3700 coating thickness gaugespaint thickness gauges can be used in many areas of industry including mfg, general engineering, commercial inspection and automotive apps.

main technical data for ptg-3700 series coating thickness gaugespaint thickness gauges:

measuring range: 0-1250um or 0-50mils

resolution: 0.1um to 100um, 1um over 100um

accuracy: +-1-3%n or 2.0um, whichever is greater

min measuring area: .2� x .2� (5mm x 5mm)

min substrate thickness: ferrous 20 mils(.5mm), non-ferrous 2mils(50um)

min radius of curvature: convex .12� (3mm), concave 1.2� (30mm)

max surface temp: 302 deg f (2 second contact)

power: 2 aaa

dimensions: 126 x 65 x 35mm (5 x 2.6� x 1.5�)

the ptg-3700 coating thickness gauges utilize an integrated probe that can automatically detect a ferrous or non-ferrous substrate and comes with 2 substrate samples (steel,aluminum), 4 calibrated thickness samples, carry case, batteries and operation manual.