Company Information

Ask for more detail from the seller

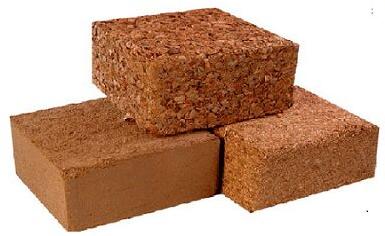

Contact SupplierCoir Fibre is extracted from the fibrous outer cover of the fruit of the Coconut palm, with or without retting. Coir Fibre is graded based on its nature of extraction, colour, presence of long and short fibres, impurities etc.

Details :

| Type | Coco Peat-Blocks | Coco Peat-Briquettes |

|---|---|---|

| Size | 30x30x12cm ± 2mm | 20x10x5cm ± 2mm |

| Weight | 5kg ± 200g | 650g ± 50g |

| Compression ratio | 0.21 | 0.21 |

| Electrical Conductivity | 0.5ms/cm | 0.5ms/cm |

| pH | 5.2 to 6.8 | 5.2 to 6.8 |

| Expansion | 70 to 80 liters | 8 to 9 liters |

| Moisture | 10 to 15% | 10 to 15% |

| Load ability | 20 tons in 40 feet HC Container | 20 tons in 40 feet HC Container |

| No. of Pallets | 20 pallets in 40 ft HC container | 20 pallets in 40 ft HC container |

| No. of pieces/Pallet | 220 pieces | 2000 pieces |

| Drying | Sun drying | Sun drying |

| Packing | Palletized with shrink film | Palletized with shrink film |