Company Information

Ask for more detail from the seller

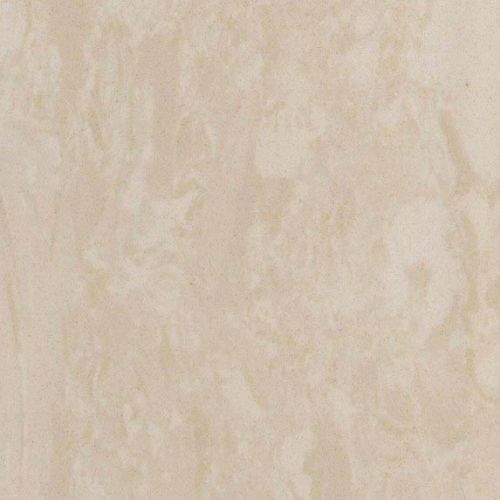

Contact SupplierWe are offering compressed marble. Compressed marble is also called synthetic stone,artificial stone,engineering stone, reconstructed stone, project stone. It takes natural marble scrap, stone powder as the main raw materials, also mosaic, shells, glass and other materials can be added as embellishment, take the organic resin as binder, through vacuum mixing, high-pressure shock, comes the semi-finished products , and then after multiple processes, such as curing at room temperature (curing time should be more than 7 days), sawing, grinding, polishing etc., get the final products.

Size

slabs: (2400mm,2700mm,3200mm)l×(1600mm ,1800mm )w×(12-40mm)t

cut-into-size: 600*600mm, 800*800mm, 900*900mm, etc. (or as per customer’s request)

product characteristics:

1. Small color difference within a large area, uniformity of color and pattern, good overall decorative effect, especially suitable for large-scale construction of pavement.

2. No radiation: strict screening is done in choosing the materials, the radiation elements contained in the stone is almost completely eliminated.

3. High strength: all hidden cracks, fissures was eliminated during production. It makes the paving process more safe. Through high-tech processing and advanced molding process, the stone is strengthened (some strength is higher than the same type of natural stone),

4. A great variety and beautiful color: the shells, glass, lens, mosaic, etc. Can be put into the stone as ornaments; and also the desired color can be done in accordance with the requirements of customers. Users may design according to their own personality and style, and make selection of varieties, present us with a unique decoration effect.

5. Stable quality: the special manufacturing process and international leading level of technology bring the product a stable and reliable quality assurance. Compared with the ceramic tile, stone has many advantages, such as multiple renovation, big size, good flatness, etc.

6. 10% lighter than the same type of natural marble.

7. Easy cutting and installation: due to the precise size and the same thickness of the products, the usual method is ok for pavement, such as joists, adhesive, cement pavement, cement bonding, dry hanging.

Scope of application:

apply to hotels, restaurants, shopping malls, airports, stations, subway and other places of large area decoration, is also the ideal material for the family room decoration and craftwork furniture making.

Guidelines before installing:

1. When using wet-hanging, wet-sticking to lay wall and column and floor, it is recommended that you use the binder or those recommended by other factories or us.

2. When flooring, please keep the floor moist and no water left (seeped), the volume proportion of cement and mortar used for leveling the floor is 1:3; the mixed cement mortar should be to the extent that it can be a group when grasping by hand and will spread when landing on ground.

3. If flooring by using the white cement, its quality and strength must be strictly checked, as the quality of different brands on market are various and some very bad ones are among them, so it is recommended that you’d better not use the white cement for big and key projects.

4. When tiles are stacked outdoors, please cover them with water-proof cloth against rain.

5. When flooring the ground, 2mm joints need be set aside between tiles to facilitate the evaporating the moisture in cement mortar and offset the expanding stress. When flooring large area, 8mm joint need be set aside every 5m in length and breadth to prevent the tiles of prominency and contraction by expanding of surface and structure.

6. When compressed tiles are used for ground flooring and use the method of flooring together with leveling, the tiles need be covered with damp cloth by 24 hours firstly before using, the joints should be filled and no steps on them 3-5 days after flooring.