Listing ID #852454

Company Information

Ask for more detail from the seller

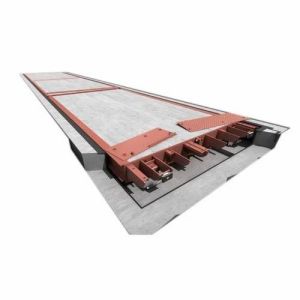

Contact SupplierOurs is a well-known firm involved in providing exceedingly efficient Concrete Weighbridge that is manufactured using strong materials in order to ensure its rugged construction. Concrete Weighbridge is economic and appreciated for its high strength, longer service life and maintenance-free attributes. Concrete Weighbridge is admired and widely used around the world due to its exemplary advantages over the steel ones. Our Concrete Weighbridge is efficient to weigh longer model trucks and trailers as it can easily bear heavy loads. An additional advantage of Concrete Weighbridge over steel weighbridge is that the former absorbs vibration when the latter not.

Advantages of concrete platform over steel platform weighbridge

| Steel Structure Weigh Bridge | R.C.C.(Concrete) weight Bridge |

|---|---|

| The price of steel W/B are quite high then RCC W/B. | Price of RCC W/B is very economical. It is almost 40% less then that of steel W/B. |

| In Steel structure W/B maintenance is more because of Looseing of nuts bolts etc. | In RCC structure is zero maintenance |

| Life span of steel stucture W/B is approx 15 years. | Life of RCC structure is approx 99 years. |

| In steel W/B vibration / Movement. |

In RCC W/B the viberation / Movement of platform is less so correspondent, accuracy is more.

|

| Annual Painting. Oiling etc is required. | Annual Painting, Oiling & Greasing are not requied. |

|

Involvement of mechanical component is there in steel W/B there for wear & tear is required. |

No mechanical components are involved there for wear & tear. |

| As steel is a good conductor of electricity lightening has a damaging effecting, load cells therefore probaility of breakdown accuracy gets disturbed | Lightning plays a vital role in the damage of load cells in RCC W/B impact of lightning is minimum because of concrete platform. |

| In steel structure W/B appreciable bending of platform occur, eggecting the alignment, of load cells therefore accuracy gets disturbed. | In concrete RCC W/B bending Effect is negigible therefore is maintained, hence more accuracy. |

| In steel structure capacity can not be increased because joist/plates and designed for a particular capacity only. |

The design of RCC W/B is such that capacity can easily be increased up to 100 Ton

|

| Anti skid ribs (strips) get affected, welding of the same put W/B out of use for some time. | Vechicle movement is controlled by rough surface RCC platform. |

| Steel of sail/Tata is expensive due to stiff competition manufacture compromise on the quality of steel resulting substandard product. | All the construction of RCC is done at site. The quality can be ensured by client on the spot. |