Company Information

Ask for more detail from the seller

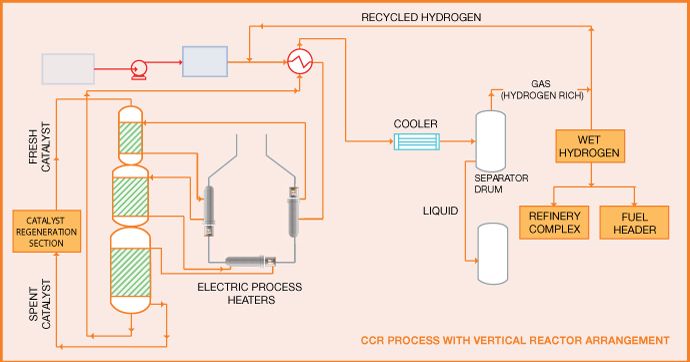

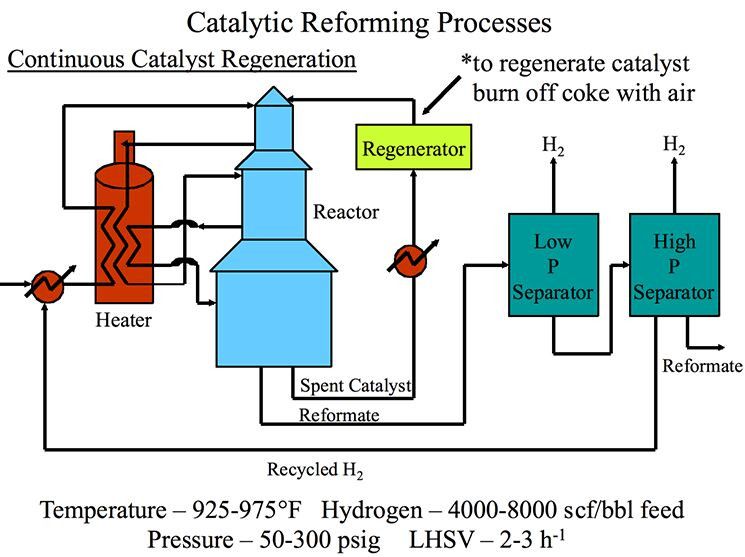

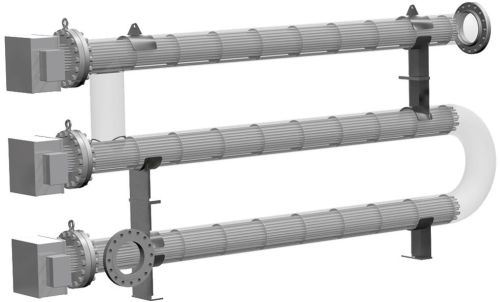

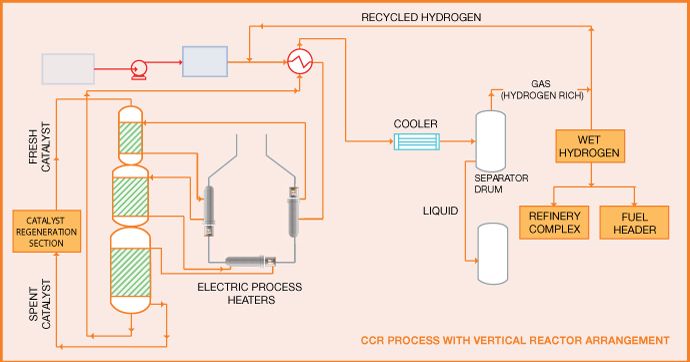

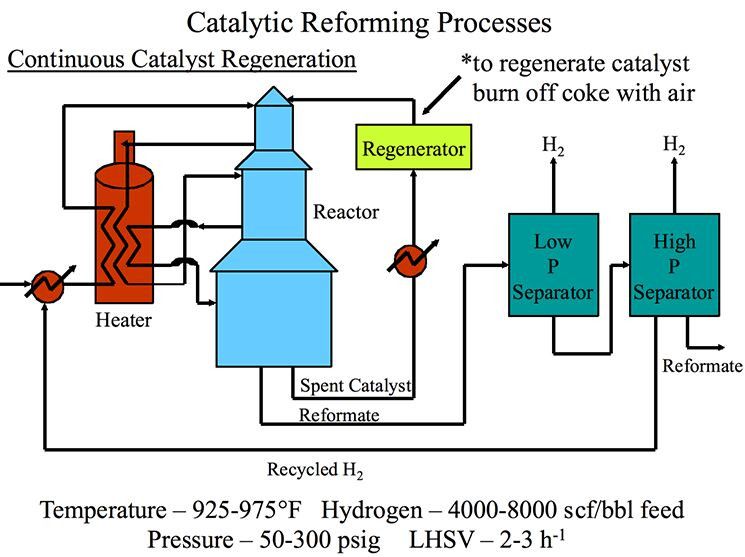

Contact SupplierContinuous Catalytic Regeneration (CCR) is a critical process in petroleum and petrochemical industries, where aromatics are produced from naphthenic and paraffinic feedstocks. During the CCR process, hydro-treated naphtha is heated to 495–535°C (923–977°F) and mixed with recycled hydrogen gas.

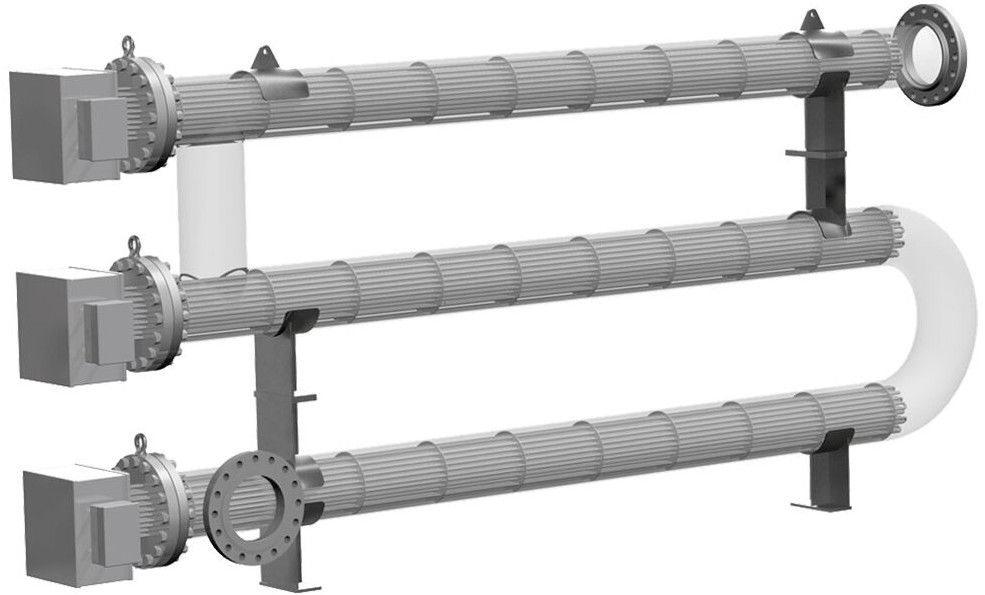

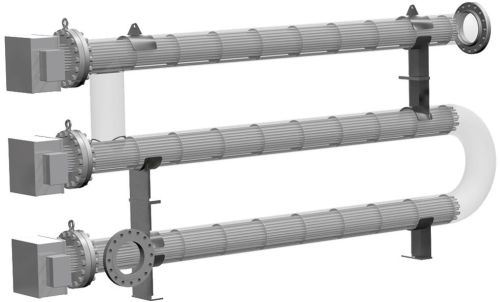

As the reactions are endothermic, multiple electric process heaters are required at different stages to maintain temperature and ensure optimal conversion.

FITZER are engineered to deliver precise temperature control, maximum efficiency, and long service life — meeting stringent licensor requirements such as UOP, Axens, and others.

Material of Construction (MOC)Heating Elements

Alloy 800 Seamless Tubes

SS 321 Seamless Tubes

Pressure Vessel

P11

SS304

SS316

SS321

Certifications

ATEX Ex'd (Flameproof)

ASME U Stamp

Other regional certifications available on request

Key Features

Compact design, ideal for integration in CCR packages

Virtually 100% efficiency due to electric heating

No fouling, eliminating frequent cleaning requirements

Precise and reliable control via thyristor control systems

Safe operation with ATEX / ASME certifications

Design Specialties

Oxy-Chlorination Heater

Calcination Heater

Burning Step Heater

Catalyst Reduction Heater

Catalyst Hot H₂ Stripping Heater

Applications in CCR Reactors

Depending on the licensor and process configuration, multiple reactors may be used in a CCR unit. FITZER provides customized electric heaters for each specific step, ensuring stable performance and long operational life.

Technical Specifications

| Temperature Range | 10°C to 600°C (50°F to 1112°F) |

| Heater Rating | 1 kW to 10,000 kW |

| Design Efficiency | ~100% |

| Control System | Thyristor-Based Control Panel |

| Design Standard | As per UOP / Axens Licensor Norms |