Company Information

Ask for more detail from the seller

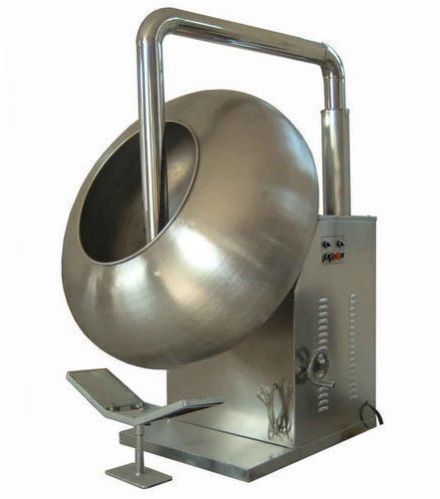

Contact SupplierProduct Description

Key Information:

Operational Features:

Customization Options:

| Model | Pan Size (Inches) | Capacity (kg/Batch) | Pan Speed (RPM) | Motor Power (HP) | Blower Capacity (CFM) | Overall Dimensions W x L x H (mm) | Approx. Weight (kg) |

| PP-CCP-12 | 12 | 02/05/25 | 20-40 | 0.5 | 100 | 600 x 500 x 900 | 100 |

| PP-CCP-24 | 24 | 10/20/25 | 15-40 | 1 | 200 | 900 x 800 x 1200 | 200 |

| PP-CCP-36 | 36 | 30-50 | 12/01/36 | 2 | 300 | 1200 x 1000 x 1500 | 350 |

| PP-CCP-48 | 48 | 50-80 | 12/01/36 | 3 | 500 | 1400 x 1200 x 1600 | 450 |

| PP-CCP-60 | 60 | 80-150 | 10/30/25 | 5 | 800 | 1600 x 1400 x 1700 | 600 |