Listing ID #4646006

Company Information

Ask for more detail from the seller

Contact SupplierSteel because of its ductile and tensile strength is widely used in auto component industry. But steel machining generally generates long curly chips. These chips are difficult to handle and donot flow with the help of pressurized coolant flow. Due to this restriction making a CFS was always a challenge.

Veeraja has now developed a unique chip cutter which can be attached to the outlet of individual chip conveyor of each machine. This chip cutter shreds the steel chips ( watch video ) into smaller manageable size. These can now be conveyed using traditional methods of gradient gravity flow.

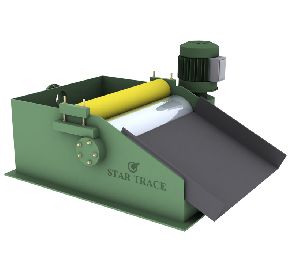

In a CFS, Dirty fluid along with chips is collected in the dirty tank. This tank has a continuously moving scarper conveyor which removes the chips that settle down. The coolant then passes through drum type magnetic seperators mounted on the side walls of the scraper conveyors. This ensures that the complete flow passes through a dense magnetic grid. The filtered fluid drops into a clean tank. Clean fluid pump supply pressurized fluid to the machines. Sizing of the tanks, magnetic drums and pumps is done based on your total flow requirement. In addition fine filter housing can be provided for through spindle coolant.

Features & Benefits