Company Information

Ask for more detail from the seller

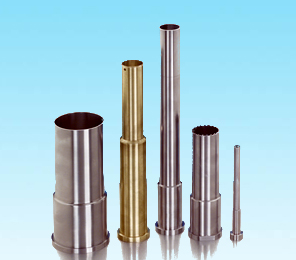

Contact SupplierService team of core pins and sleeves---YIZE MOULD is ready for serving you

In order to ensure the quality of 【core pins and sleeves】, we must pay attention to details, put an end to rough manufacturing, stick to their posts, and set up the correct concept of work. Only by doing this and constantly strengthening can we become a competitive manufacturer of core pins and sleeves.

asdyizesw

Category:Core pins and sleevesrnProduct name:ejector sleevesrnProduct size: customizationrnMaterial:Japan(SKD11.SKD61.SKH51.S45C)rnUSA(AISA.D2.H13.P20.M2)rnGermany(DIN.2379.2363.2344.2347)rnASSAB(Rigor.Stavax.Impax.Elmax.ASP23)rnHardness:58-60 HRCrnGrinding precision:0.001mmrnElectric discharge processing precision:0.002mm

We have more than ten years of experience in the processing of tungsten steel parts, connector die processing, and core pins and sleeves processing. The Waida optical curve grinding machine imported by Japan ensures the grinding precision of 0.002mm for tungsten steel parts, and we can also complete the TIN, TICN, TIALN and other electroplating of the workpiece according to the requirements of the customers.