Company Information

Ask for more detail from the seller

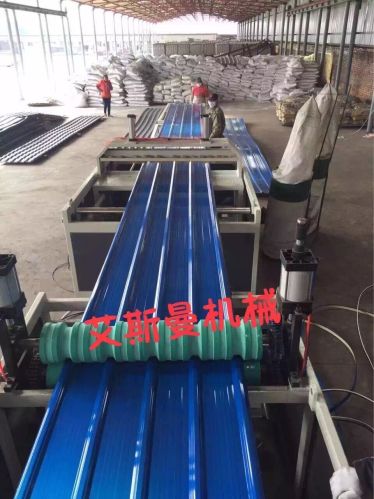

Contact SupplierWe are offering corrugated roof sheet making machine.

Pvc corrugated roof tile making machine:

this tile is the best replacement to conventional asbestos, metal g.i. Sheets and pvc sheets considering the heat insulation, sound insulation, water resistance, chemical and alkali resistance, corrosion proof, fire retardant, eco friendly, easy to install and move, light weight as well as cost effective in installation (as less steel and less overlap), as per the efficiency and benefits it provides.

It can save construction cost upto 50%.

apart from its numerous benefits, its salient features include heat insulation upto 35% (highly energy efficient) and it can withstand temperature upto 70 degrees celsius to - 40 degrees celsius which is very much suitable for your market.

1)pvc one layer pvc+asa two layerpvc+pvc+asa three layer pvc+pvc+pvc+asa four layer .asa layer for anti-uv for 20-30 years life.

2)corrugated tile width 920mm1130mm,thickness 1.5-3mm adjustable.

Other product width can be customized.

3)plastic corrugated tile have the same product structure with metal sheet.

4)trapezoid or round shape for your choice.

5)the turnkey machine contain main tile extruding machine,ridge tile forming machine,mixer,crusher,pulverizer

6)plastic corrugated tile are used for roofing, can be used for factories, warehouses, sheds, farmers market, hoardings, walls, temporary shops, sheds and other very suitable insulation

raw material & formulation:

pvc powder, caco3, cpe, pe-wax, stearic acid , compound stabilizer ,acr, paraffin

asa granule

width:9201130mm,thickness: 1.5~3.0mm;

output:300-400kgh(depending on caco3 proportion)