Company Information

Ask for more detail from the seller

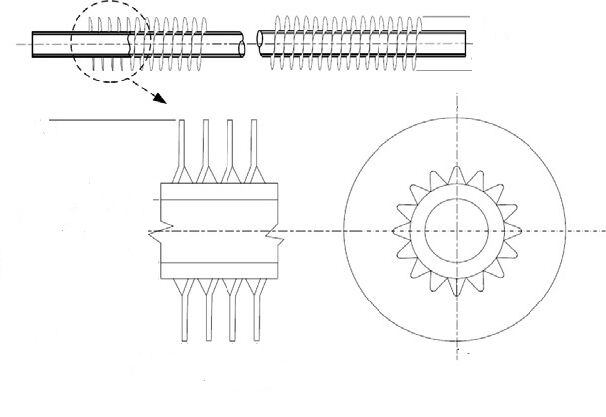

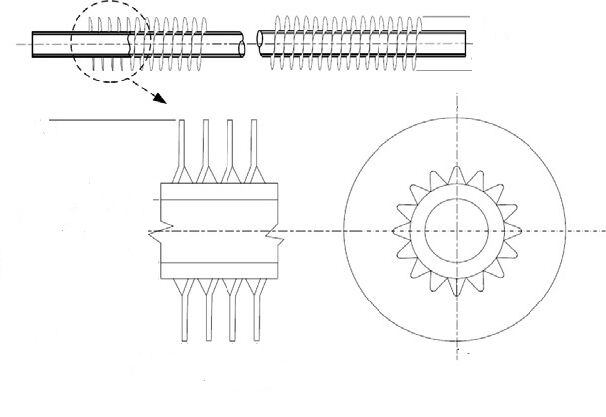

Contact Supplierthe crimped fin tubes also known as spirally tension wound finned tubes is a very widely used finned tube type for a various number of applications.

as the name suggests the manufacturing of crimped finned tube (spiral tension wound fin tube) is done by tension winding of fin material on the base tube. the base tip of the fin strip is pre formed on a set of performing rollers.

this pre forming allows for a wider base and hence contact area is increased. it also enables more turbulence for the air flowing over the finned tube thereby increasing heat transfer efficiency. the ends of fins are tag welded to secure its bond on the base.

this finning takes place on dedicated specially designed finning machines with auto feed mechanism. this process allows a very long length of tubes to be finned.

it finds application in various industries ranging from driers, radiators, heaters etc and are used in many industries like food, chemical, oil cooling etc.

manufacturing range (crimped fin tube/spiral tension wound fin tube):-

| 1 | base tube material | stainless steel, carbon steel, alloy steel, titanium, copper, duplex stainless steel, and inconel etc. (all material in the theoretical limit) |

| 2 | base tube outside diameter | 15.88 mm to 219.00 mm od (⅜” nb pipe to 8” nb pm) |

| 3 | base tube thickness | 1.00 mm and above |

| 4 | base tube length | 500 mm min to 15000 mm |

| 5 | fin material | aluminum, copper, stainless steel, carbon steel. |

| 6 | fin thickness | 0.15mm, 2.00mm |

| 7 | fin density | 118 fpm (3 fpi) to 433 fpm (11 fpi) |

| 8 | fin height | 6 mm to 25.40 mm |

| 9 | bare ends | as per client requirement |

| 10 | manufacturing capacity | 4,00,000 meter per annum |

we can supply material on an urgent delivery basis because of large stock and relations with raw material suppliers. we use only prime quality base tube and fin material.

the crimped fin tubes (spiral tension wound fin tube) can be supplied with en 10204 en 3.1 and en 3.2 certifications. we can provide third party inspection from any reputed inspection agency.