Company Information

Ask for more detail from the seller

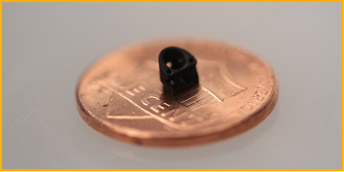

Contact SupplierProPlas Technologies was hired by a customer in the medicaloptics industry for the design and manufacturing of the plastic components of a disposable endoscope. This highly precise, multipart device is used to view inside of a body cavity or organ. Based upon customer requirements, we designed these highly intricate components with DFM (Design for Manufacture) in mind and selected PCABS alloy as the production material. An LED, camera, and two mirrors were incorporated into the design of the smallest component (3mm diam. x 2.5mm tall). Various sizes of electric injection molding machines were utilized in the molding of these components and micro-molding of the smallest component. The tightest tolerance of ±0.0002" was achieved in production. Pad printing was used to imprint the branding and identification markings.

Final dimensions of the endoscope were 24" in length, with a smallest diameter of 3mm and a larger diameter of ¾". Dimensional and visual testing procedures were implemented to verify accuracy. This project met customer specifications as well as FDA, ISO 9001 and ISO 13485 standards covering medical devices. Turnaround time for the design work was 5 weeks, tooling 14 weeks and production leadtimes are 4 to 5 weeks, with shipments to the customer for incorporation into the finished assembly and subsequent shipment throughout the USA.

For more details about medical device component design, molding and fabrication, or the other capabilities available please see the table below or contact us directly.