Company Information

Ask for more detail from the seller

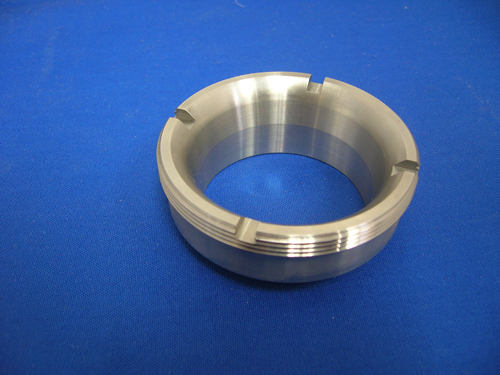

Contact SupplierThis featured insert orifice is used in natural gas extractions, and is composed of 316 stainless steel. To manufacture the insert, a variety of CNC machining processes were applied. Using a Haas CNC lathe with live tooling, we turned each side, with the second side requiring a 12″ precision radius on top of a 15 degree lead-in angle. Next, we milled 4 slots 90 degrees apart, with .125″ in depth through 2 78″-16 UN-2A threads. Throughout the machining process we maintained tight tolerances of +.000″-.005″, and a concentricity tolerance of .004″. To conduct inspection we relied on an OGP touch probe and a vision system CMM, as well as micrometers, pin gages, a custom thread gage, a drop gage, and an optical comparator.

The final insert orifice featured 3.00″ round bar stock, with a 2.750″ outside diameter and a 2.020″ to 2.5625″ inside diameter. Each of 4 slots measured 2.188″ wide, and the total insert weighed 12 lb. We then labeled each carton with part and lot numbers, as well as the quantity. Packaging was limited to 60 parts per box, with each box weighing a maximum of 40 lbs. Included in each order was a raw material certification, complete with chemical and mechanical properties, and quality control verification. The project took 4 to 6 weeks to complete, and was then shipped to our client for use in the oil and gas industry.