Company Information

Ask for more detail from the seller

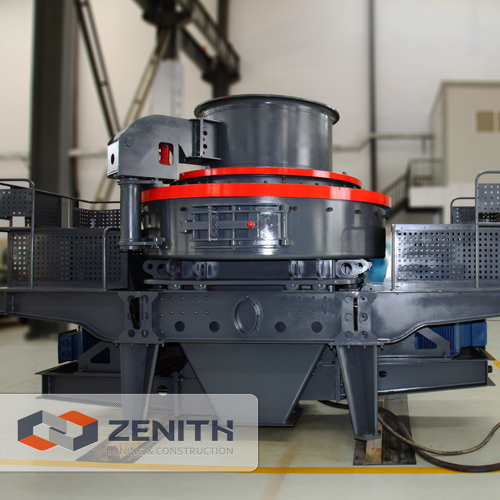

Contact SupplierWe are offering B Series Deep Rotor VSI Crusher.

B Series Deep Rotor VSI Crusher is a new generation and high effective product which introduces German technology, and owns many independent patent properties. It integrates three crushing methods into one. All of these made it the core equipment in sand making industries. It is widely used in a variety of metallic and non-metallic minerals, cement, refractories, abrasives, glass raw materials, construction aggregate, sand, metallurgical and other industries. Be applicable for medium and fine crushing of various ores and rocks, such as iron ore, non-ferrous metal ore, corundum, bauxite, quartz sand, perlite, basalt materials. It incorporates three crushing styles: material on material, material on iron and falling at side. It is widely used in a variety of fields such as minerals, cement, sand, metallurgical and other industries.

Features

1. Deep cavity-type rotor design is optimized to increase material pass-through volume by 30%.

2. Modular-design hammer, just to replace worn parts when wear out, it can reduce cost more than 30%.

3. The core abrasion-resistant material is high degree wear-resistant and temperature-resistant material.

4. Diamond-shaped impact block avoids stand plate being damaged after wear out.

5. Bearing use Swedish and American international brand.

6. Optimal shooting mouth and more fluid curve-shaped design reduce the resistance to the material flow, improving material pass-through capacity as well.

7. Special seal structure in the spindle end, ensure no oil leak even without oil seal.

8. Hydraulic openings device uses Japan imported parts, it is easy and quick to move upper lid, so the internal mechanical overhaul and replacement cost less labor effort.

9. Using high protection motor, which features high efficiency and low noise.

Technical data

Model Feed at center&sides Feed at center Soft Material Hard Material REV (r/min) Power (kw) Motor Model Machine Size (mm)

Capacity (t/h) Max Feeding (mm)

B-7615DR 150-280 70-140 35 30 1700-1900 4-75×2 Y280S-4/75 4100×2330×2300

B-8522DR 240-380 120-190 40 35 1500-1700 4-110×2 Y315S-4/110 4140×2500×2700

B-9532DR 350-540 180-280 45 40 1300-1510 4-160×2 Y315L1-4/160 4560×2600×2900

B-1145DR 500-640 250-360 50 45 1100-1310 4-220×2 Y355M1-4/220 5000×2790×3320

Zenith service

Pre-sales Service:

The wide product range enables us to provide our customers with individual machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions, and we produce strictly follow customers’ order. What’s more, every customer has the chance to visit the working machine in the site before placing the order.

Most of the visiting foreign customers feel inconvenient for the first time. Due to this condition, we help to arrange cars, hotels, and translators for every visiting customer.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees, and installation engineers. The installation technicians are special and professional team of Zenith; they are now strategically located home and abroad, working for our customers.

Contact us

Head office address: No. 416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

Zip: 201201

Tel: 0086-21-58386256 0086-21-58386258

Fax: 0086-21-58385887

Email: info@zenithcrusher.com

Website: http://www.zenithcrusher.com/