Company Information

Ask for more detail from the seller

Contact SupplierInnovative testing with FOERSTER

The DEFECTOVISION IR system is an addition to FOERSTER's core competence, the non-destructive testing of semi-finished metal products. All around the world, more than 6.5 million tons of steel have been tested safely and efficiently by now with our latest technology.

The automatic infrared technology applied by FOERSTER provides new approaches for previously impossible testing tasks.

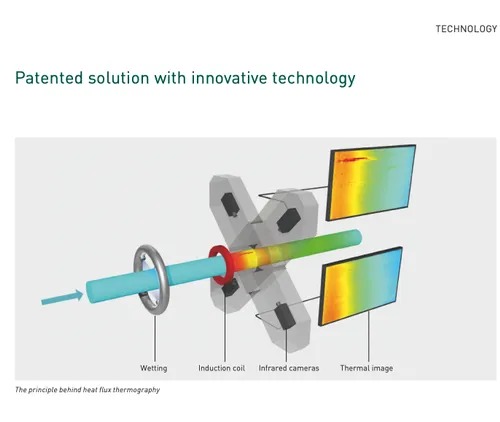

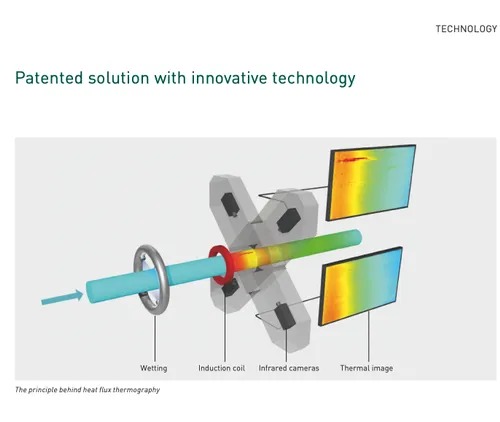

Inductive heat flux thermography facilitates the testing of entire surfaces of hot-rolled steel billets and tubes with round, square, or rectangular cross-sections as well as rails and profiles. Flat surfaces as well as exterior and interior radiuses are tested fully and reproducibly. All but a few millimetres of the ends of the materials are also covered by the surface test.

Technical Data:

Test products: Round and square ferromagnetic steel billets

Diameter / edge length: 50 – 300 mm

Test product length: min. 4 m

Max. test speed: 1.5 m/s

Untested ends: type 5 mm

Minimum defect depth: 0.3 mm

Minimum defect length: 10 mm

Your advantages at a glance:

• Fully automatic testing of round and profiled steel billets, tubes, and rails

• Adjustable defect thresholds for targeted depth selection

• Reduces repair costs by suppressing incorrect warnings

• Comprehensive electronic documentation of the test results

• Integration in existing production and quality systems

• Contactless and non-wearing technology

• Compact design for integration in existing production lines

• High throughput

• Test fully covers the entire material surface

• Detection of even the smallest material defects