Company Information

Ask for more detail from the seller

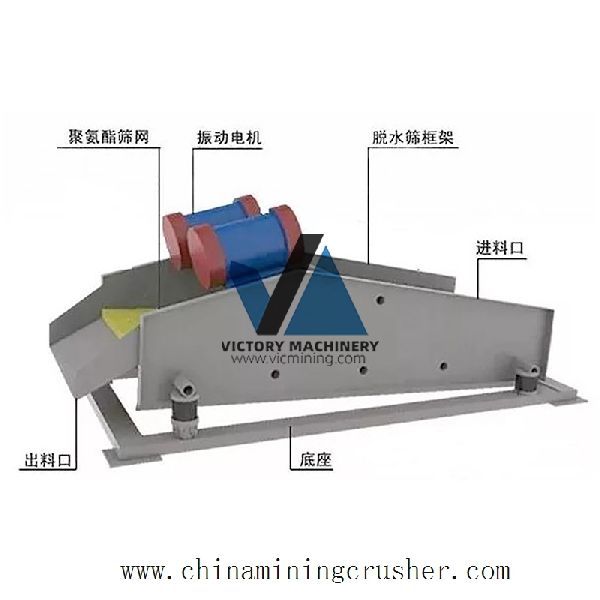

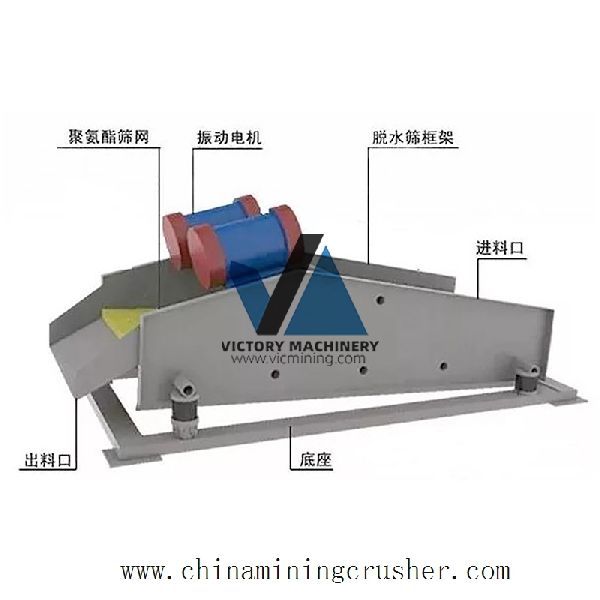

Contact SupplierDewatering screen is mainly used for dewatering, desliming and demineralization. It can be used for washing sand in sand and stone plant, recovering slime in coal preparation plant, dry discharging of tailings in ore dressing plant, etc. Therefore, it is also called sand dewatering screen, mining dewatering screen, slime dewatering screen, tailings dewatering screen, high frequency dewatering screen, etc. Although they belong to the same dewatering equipment, the structure of the dewatering screen is different when it acts on different materials, such as the sand dewatering screen on the water washing sand production line and the tailings dewatering screen commonly used in the concentrator. The vibrating dewatering screen is mainly used in the wet sand production line, which can be used with the sand washing machine or alone.

Function introduction

Use with sand washing machine

Why should they be used together? We should know that the sand washed by the sand washing machine is not very clean in fact. The sand not only contains a certain amount of mud and is too wet (with large water content), but also does not meet the production needs of low standard and high standard of sand mud content. Therefore, it is necessary to configure a vibrating dewatering screen for dewatering and desliming! After the sand is cleaned by the sand washing machine, the desliming and dehydration screening treatment of the dehydration screen can achieve a reasonable particle size ratio and reduce the mud content to less than 0.7%.

Use the dewatering screen alone

The dewatering screen can also be used alone when it acts on some materials with low mud content, without the need of a sand washing machine, such as quartz sand. Because of the low mud content of quartz sand, washing sand with water by sand washing machine not only consumes energy but also has poor effect. More importantly, the investment cost of dewatering screen is lower than that of sand washing machine.