Listing ID #2398639

Company Information

Ask for more detail from the seller

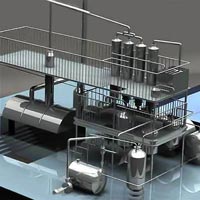

Contact SupplierWinterisation is an operation designed to preserve limpidity and refined oils brightness.

The Dewaxing process consists in removing from these oils, mainly maize and sunflower, small quantities of solids that cause cloudiness when the oil is kept at ambient or low temperature. These solid substances can be saturated glycerides or waxes. Thanks to the relatively small amount of solids - between a few hundred and 2000 ppm - winterising is a continuous and, therefore, cost-effective process. In order to obtain an oil with good stability, the wax content needs to be reduced to a level of less than 10 ppm. To achieve this, the variables of time, temperature and agitation require special care to produce oil in a closely controlled range.

The process is conducted in four steps :

Dewaxing Major Advantages