Company Information

Ask for more detail from the seller

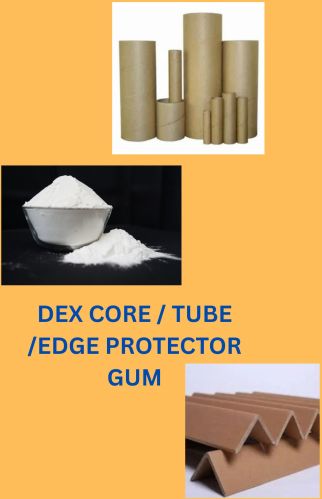

Contact SupplierOur product is used in the paper tube and paper core manufacturing industries. We offer a wide range of paper tube gum powders in different grades and colours to meet the needs of our customers. The product is manufactured with the highest quality raw materials and advanced machinery, which enables us to provide our clients with superior products.

Role of Adhesives in Core / Tube Compression value

Assembly of ply one over the other is basic operation. Theoretically contact area of fibers of two layers is very low. Adhesives fills the gaps between the payers and penetrate both the layers. Even Though this penetration may not cross 20 microns, it is significant to hold both the layers together. Tack of adhesive defines the speed at which machines can run assuming all other conditions remaining the same. To get appropriate bonding there needs to be balance between paper parameters like COBB, formation, ply-bond GS etc with glue properties like viscosity , solids , flow , tack etc. Lamination of plies in the middle, top and inner area of core is different. Even poor lamination in few layers can cause drastic fall in compression value.

Applications:

It is used in Paper Tube, Paper Core, Spiral Tube & Edge protector Manufacturing.

Advantages of Dex gum products

● Excellent Tack.

● Fiber to Fiber lamination initiates in less than 180 sec.

● Consistent viscosity for given water mix ratio.

● Expertise in understanding customer process parameters and technical capabilities to produce product to suit the process parameters.

● Higher compression values.

● No slippage even at higher application.

● Fast setting property.

● Low application and consumption.

| PRODUCT NAME | RATIO | SOLID CONTENT |

| DEX CORE GUM 115 | 01:01.2 | 48% |

| DEX TUBE GUM 200 | 1:02 | 33% |

| DEX TUBE GUM 300 | 1:03 | 25% |