Listing ID #1528886

Company Information

Ask for more detail from the seller

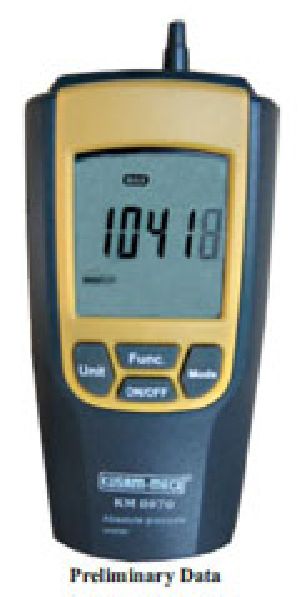

Contact SupplierClients can avail from us cutting-edge Differential Pressure Flow Meters. These Differential Pressure Flow Meters are made as per the international quality norms and are highly reliable. In these Differential Pressure Flow Meters, there is a turbine meter that consists of a practically friction-free rotor pivoted along the axis of the meter tube and designed in such a way that the rate of rotation of the rotor is proportional to the rate of flow of fluid through the meter. This rotational speed is sensed by means of an electric pick-off coil fitted to the outside of the meter housing. The only moving component in the meter is the rotor, and the only component subject to wear is the rotor bearing assembly. However, with careful choice of materials (e.g., tungsten carbide for bearings) the meter should be capable of operating for up to five years without failure.

There are several characteristics of turbine flow meters that make them an excellent choice for some applications. The flow sensing element is very compact and light weight compared to various other technologies. This can be advantageous in applications where space is a premium.

Other Details

| Payment Terms | L/C (Letter of Credit) |

| FOB Price | 100000 INR |

| Port of Dispatch | At Ex.Factory Works |

| Production Capacity | 1000 Units per Week |

| Delivery Time | Immidiate if Required |