Listing ID #4199432

Company Information

Ask for more detail from the seller

Contact SupplierPharmachine is now offering Digital Die-Punch Inspection Kit for inspection of Toolings which facilitates the operator to measure and automatically record the dimensions of the Toolings on his/her personal computer for easy monitoring of the Tooling quality and store data of each set of Tooling for lifetime.

As continuous usage of Die-Punch on the Tablet Compression Machine causes lot of wear and tear leading to several types of problems, it is prudent for the engineering department to inspect each and every Die-Punch set and store the data in the computer.

The periodic storing of data of a particular set of Die-Punch on the computer will reveal any short coming on the quality of the Tooling or the need to reject any Tooling in the process of measuring and monitoring the dimensions. This kind of data set up of different types of Toolings on a PC helps to avoid any major break-down of the Tablet Compression Machine or avoid costly production losses by weeding out bad quality or worn out Toolings on a periodical basis.

Normally a Tablet production department can confront any of the following problems due to continuous wear and tear of Toolings:

To co-relate the above problems one has to check the following parameters on each of the Tooling set:

The Inspection Kit can also be used for checking Cup Depth, Punch diameters, Die outer diameter, Die height etc. The major advantages of using Computerized Die-Punch Inspection Kit over conventional or manual Inspection Kit are as follows:

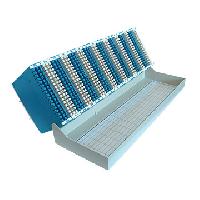

Contents of Inspection Kit: