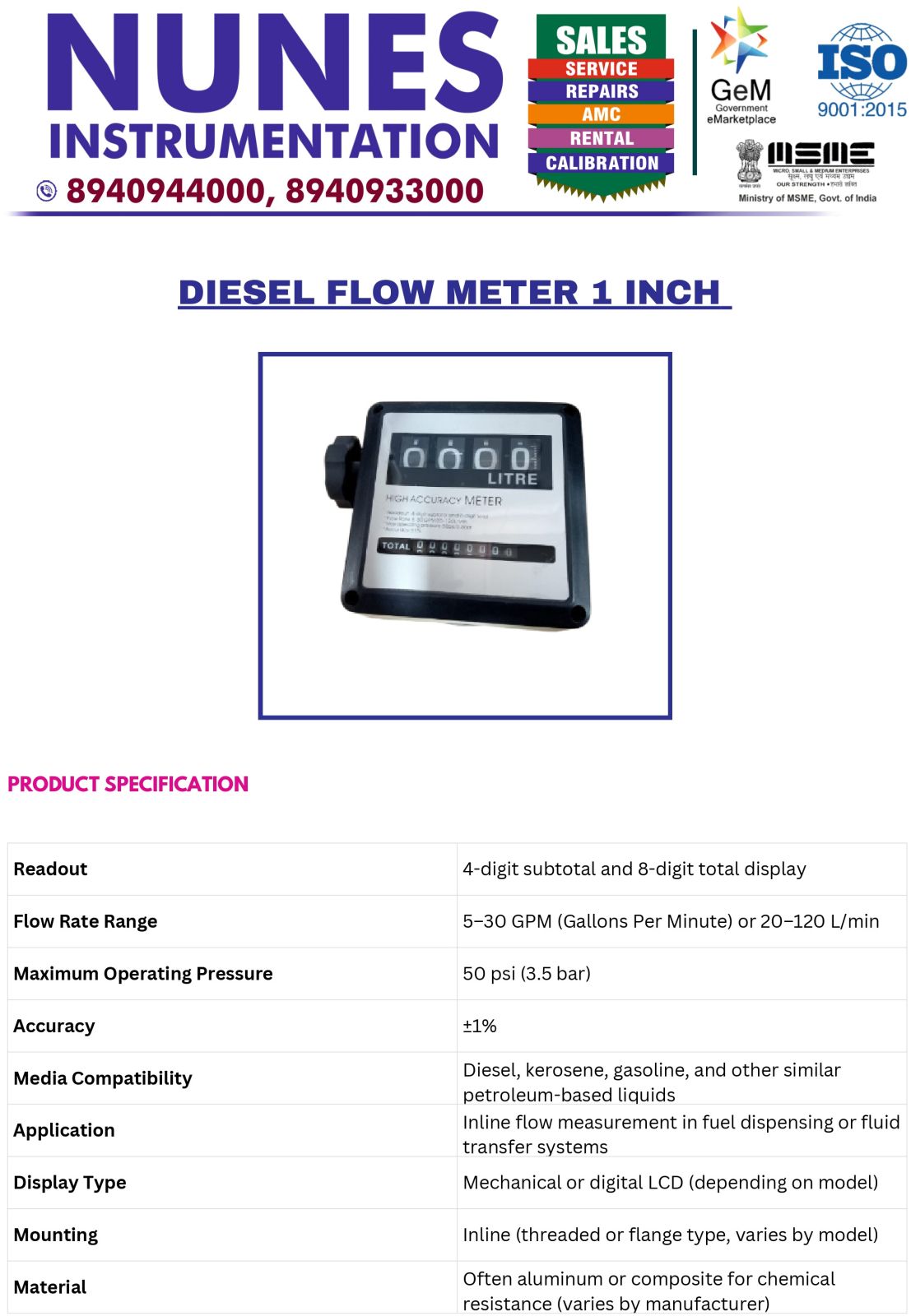

Company Information

Ask for more detail from the seller

Contact SupplierA Diesel Fuel Flow Meter is a flow-measurement instrument designed for accurately measuring the volume (and often rate) of diesel (and other petroleum fuels) flowing through a pipeline segment. In the specified line-size range (25 NB to 100 NB) it is suitable for medium-duty industrial fuel handling, bunkering, diesel-tank-feed systems, generator supply lines, fuel-transfer skids, etc.

The unit typically uses a positive-displacement (e.g., oval gear) or turbine principle, providing high accuracy, good repeatability, minimal sensitivity to viscosity changes, and robust construction for fuel-service environments. For example, one Indian supplier lists: line size 25 NB to 100 NB, operating temperature up to ~70 °C, flow range ~20-120 L/min, accuracy ~1%.

Key Features

High accuracy volumetric measurement of diesel and fuel oils — ensures correct billing/transfer and inventory control.

Minimal sensitivity to fuel viscosity changes (important when temperature varies or fuel grade changes) — ensures reliability.

Robust construction for fuel-service conditions: compatible with diesel, low sulphur fuel oils, light/heavy fuel oils, non-corrosive fluids.

Available in a wide size range (25 NB-100 NB) making it suitable for various fuel line applications from small generator feed lines to bulk fuel transfer lines.

Integral totaliser/display for cumulative flow monitoring and optionally flow rate display.

Some models provide remote/pulse output or digital interface for integration with automation (SCADA, PLC) or inventory management systems.

Easy maintenance and calibration — beneficial for procurement in industrial fuel systems where downtime must be minimal.

Low pressure drop designs (especially in well-designed positive displacement meters) reducing pumping costs and pressure loss.

Here are typical use-cases where this Diesel Fuel Flow Meter would be used (relevant to your instrumentation procurement context):

Generator fuel supply lines in industrial plants — to monitor fuel consumption accurately for cost allocation and maintenance scheduling.

Marine or bunkering fuel transfer systems where accurate volumetric metering of diesel or fuel oil is critical for fuel custody and transfer.

Fuel storage and dispensing facilities (diesel bunkers, tank farms) where volumetric flow metering ensures correct inventory and sales/distribution measurement.

Fuel-oil transfer between tanks and burners (in power plants, heating plants) — ensures accurate monitoring of fuel usage and process control.

Vehicle fueling stations, diesel bowser feed lines, forecourt fuel transfer systems — for accurate billing and leak monitoring.

Petrochemical and refinery internal fuel circuits — to monitor internal fuel usage, optimize process efficiency, and detect anomalies