Company Information

Ask for more detail from the seller

Contact SupplierDPM-direct part marking (This includes both human readable and data matrix codes)

Marking Methods : Laser, Dot peen, printed labels etc.

Objective : Objective of marking Data matrix along with human readable codes is as under.

Factors which control data matrix code quality and its readability at various stations.

Laser Marking

Laser marking is a non-contact thermal process where the heat generated by the beam alters the surface of the tool. When the temperature is raised in a localized area, carbon will precipitate out along grain boundary areas turning black.

Advantages of laser marking

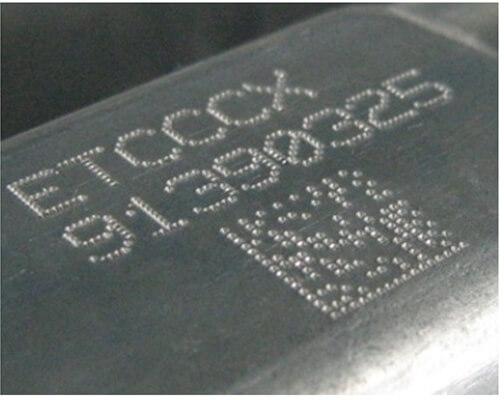

Dot Peen Marking

This is contact type of marking;where in a carbide pin marks a series of dots to form the matrix. Its also governed by the ECC200 norm for marking.

Advantages of dot Peen marking

Disadvantages of dot Peen marking

Printing

This is again just like a normal sticker printing unit, good for application where outside contact with the part is limited, so that the lable is not getting damaged, very limited application but.

Vendor Selection

Success in implementing a DPM application depends upon many factors that have been outlined in this document. DPM is a very challenging application requiring technology and know-how in solving difficult image analysis problems. Typically, companies experienced in industrial machine vision have the right know-how and technology for providing the highest DPM read rate.The vendor should provide the support necessary to thoroughly qualify your DPM application, and guide you through the considerations necessary to ensure installation success.This can be especially important if the system is commissioned in one location and shipped to another. And finally, the selected supplier should have a successful track record and financial stability to maintain their role as your DPM marking and reading solutions provider for the long term

Verdict

From our experience, we would recommend laser marking where ever possible as it's the only method by which you can get high contrast codes on almost any surface, which improves readability at various levels.In India we have installed more dot peen systems than laser but it's only because of price. If that's not your first criteria then you have got the answer.

Traceability Solutions For Marking, Direct Part Marking Machine, Direct Part Marking Machine Manufacturer, Direct Part Marking Machine Exporter, Direct Part Marking Machine Suppliers

Direct Part Marking Machines manufacture, supply and export in various location like Pune, Mumbai, Chennai, Bangalore, UP, Bihar, West Bengal, Jharkhand, Chhattisgarh, MP, Orissa, Maharashtra, Goa, Karnataka, Andhra Pradesh, Kerala, Tamil Nadu, Telangana, Assam.