Company Information

Ask for more detail from the seller

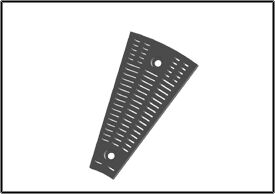

Contact SupplierAs the prominent Indian manufacturer and supplier of the best quality rubber products, Kedar Rubber offers custom design solutions for discharge cones broadly used in ball mills for different applications. In the ball mill, the discharge cone is located at the end part from where the ground material comes out. It impacts the flow of grinding material, energy efficiency, and durability of milling in addition to the product quality. Hence, the cone-shaped or conical design discharge cone prevents blockages and allows optimal segregation of finely ground materials. Thus, it plays a vital role in prolonging the mill's lifespan and improving its performance.

All About Discharge Cone for Ball Mills

Once the particles of the processing material reach the desired particle size, the discharge cone allows them to exit from the ball mill. The conical shape prevents clogging and controls a constant material flow; hence it makes it possible to reduce blockages that interrupt the milling process.

The discharge cone in the ball mill also helps reduce wear resistance on mill liners. It withstands abrasions that occur due to the grinding particles when moving through the ball mill by making the smooth & uniform material flow. Thus, it reduces energy consumption for pushing material out from the ball mill and makes the process energy efficient.

We provide custom design solutions to supply discharge cones as per the type of your ball mill discharge such as overflow discharge or grate discharge. Both types of discharge cones help regulate the flow of grinding materials and improve mill performance. Based on the needs of different industries like mining, ceramics, or others, the discharge cone design can be customized. Based on the type of grinding material, the durability of the cone is required, so that it can withstand the abrasive nature of the material. The conical design selection in some ball mills is necessary to enhance internal motion and better mixing of the material and ensure uniform material grinding throughout the process.

For more information or your custom inquiry for the best quality discharge cone for ball mills, write to us at or Call Now - 9824444733.