Company Information

Ask for more detail from the seller

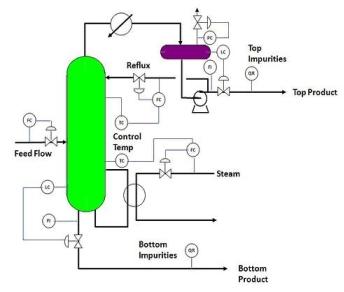

Contact SupplierDistillation has been in practice for centuries. But we at Fenix over the years have developed an integrated engineering capability to meet all your needs on distillation. Along with process design, we possess high efficiency in

Scope of our work includes right from basic design of one piece of equipment to complete turnkey process. From the enquiry stage itself we are continually in touch with our esteemed clients at each stage of process calculation, validation of data & results, detailed design, GA drawing, process simulation if needed, engineering drawings and design package (process & mechanical) including specifications. We also provide distillation systems entirely according to customer̢۪s specifications.