Company Information

Ask for more detail from the seller

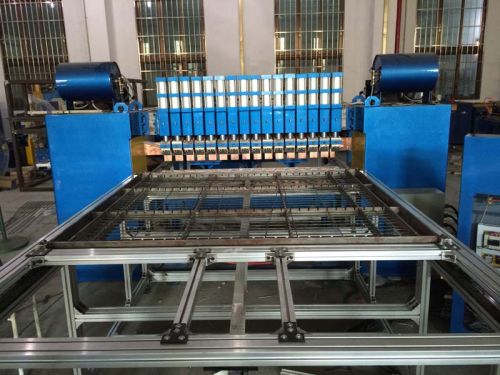

Contact SupplierBasic structure description on machine is as follows:

1.1 This equipment is mainly including(1)Mainframe,(2)Press structure,(3)Main welding circuit, (4)Crosswire pitch automatic feeding equipment,(5)Longitudinal pitch feeding equipment,(6)Drawing mesh system and (7)controlling system, etc.

1.2 Mainframe including main body outer iron crust and slider chassis. It apply to quality steel, which is through welding, heat treatment (to eliminate stress) and precision machining to guarantee the necessary rigidity and precision requirements of work piece.

1.3 Press Structure: it apply to the way of cylinder vertical compression of cam driving by motor, greatly accelerate the reaction rate movements, improve the production efficiency. The compression rod plating the rigidity chrome after exactitude polish.

The Welding Process as follow:

Manually load lots of crosswires together to the up crosswire feeding box and feeding the longitudinal wire manually one by one → Press the “start” button →Automatically feed the crosswire to the welding station gate → Longitudinal pitch feed automatically → Cylinder press at one time and welding one by one then replacement →Drawing mesh system feed the metal mesh to the next welding station →Cross wire and Longitudinal wire feed automatically → Cylinder press at one time and welding one by one then replacement →Repeat the welding process until finish the full welding.

Main Technology Parameter:

1 Model Number: DNW Series

2 Input Electrical Source:AC 380V 50HZ(or Custom-Made)

3 Max Welding Width: 3000mm

4 Welding Speed:≤30timesmin

5 Wire Diameter:5-12mm