Company Information

Ask for more detail from the seller

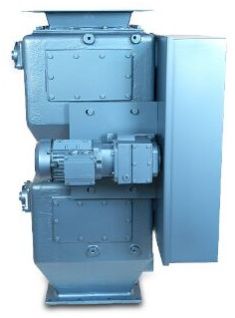

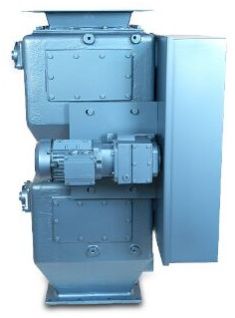

Contact SupplierCast iron casings which are robust and hard wearing Fabricated casings for non-standard sizes and specific applications Motorised actuation as standard with optional gravity counterweight or pneumatics Re-greasable shaft bearings with optional seals to suit the application All models and sizes available to suit high temperature applications Machined inlets maximise clapper plate closing efficiency Suitable for discharge dry dust, powder, granules and fibrous materials from cyclones, filters, hoppers etc., whilst maintaining an effective airlock. The valve consists of two flaps connected by counterweights or spring loaded spindles, which are operated by means of a motor driven cam. The cam alternately opens each flap allowing materials to pass through the separate chambers in batch form and thereby ensuring an airlock. After cam release, the counterweights (or springs), return each flap to the upper (sealed) position and are designed and sized so that a clapping action at the flaps is obtained, aiding material flow and preventing build up at the seal plate. The unit is suitable for pressure differentials of up to 500mm W.G. This can be increased with special features. A fabricated steel body caters for sizes and specials that fall outside the standard 150, 200, 250 and 300mm cast iron body range as well as offering stainless steel construction. Optional hardened steel flaps and inlets can help prolong the valve life in particularly arduous or abrasive applications.