Company Information

Ask for more detail from the seller

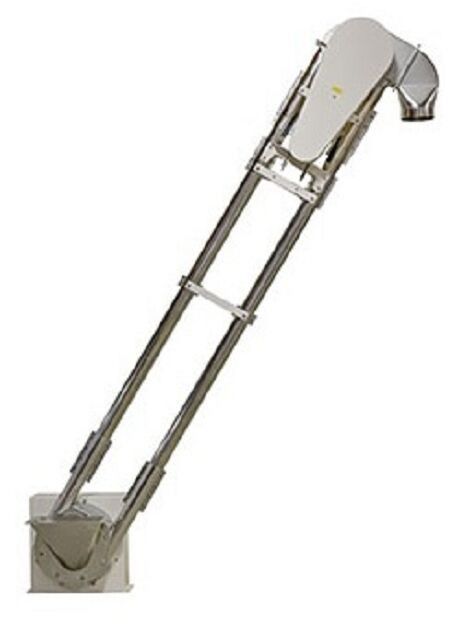

Contact SupplierTUBULAR CHAIN DRAG CONVEYOR

PneuCONVEYOR – Tubular Chain Drag Conveyor design acts as a universal joint during product transportation in the pipe which enables a single conveyor to achieve directional changes in multiple planes, including 90 degree turn.

pneuCONVEYOR – Tubular Chain Drag Conveyor system includes many accessories such as Brush Assembly or Chain Knockers for cleaning of the chain, Drop Bottom or Slide Gate Valves for immediate discharge of the product, or a Turn Station which replaces 90°elbows to reduce wear and tear on the discs & chain. The Tubular Chain Drag Conveyor is the best solution for material handling applications.

Available in 4”, 6”, 8”, 10” & 12” diameter. Available in Carbon Steel Construction, Stainless Steel Construction, and Clean-In-Place Systems for Food & Pharmaceutical Applications.

Descriptions:- The tubular chain drag conveyor (also called a tubular drag link-chain conveyor ) provides gentle, enclosed continuous transfer of bulk solid materials, including fine powders, granules, pellets, and moist sludge’s, at any angle, in any plane, and around any obstacle. The chain links in the conveyor’s chain-and-disc conveying mechanism function like universal joints, enabling the conveyor to simultaneously move material in multiple directions and planes. The conveyor also has a low-profile, flexible design that allows it to fit into tight spaces around existing plant equipment.

Widely used in pharmaceuticals, Chemicals, Food, Snacks, Minerals, Dyestuff, Pesticides, Fertilizers, Plastics, Pint and other industries, the tubular drag chain conveyor can be equipped to handle highly abrasive or hot materials also, meet sanitary requirements for transferring foods and pharmaceuticals, and safely convey potentially explosive materials — all at a much lower operating cost than that of a comparable pneumatic conveyor.

How the conveyor works :- Components : The tubular chain drag conveyor consists of a tubular housing enclosing a continuous chain mounted with solid circular discs (or flights), often called a chain-and- disc assembly, The housing can include straight and curved sections constructed of carbon steel or stainless steel pipe with a typical nominal diameter of 2 to 12 inches. The housing forms conveying and return lines that can be arranged in multiple configurations, including complex loops with several turns, to suit the application layout.

A drive sprocket engages the chain-and-disc assembly at the turn at the conveying line’s end. A shaft-mounted motor, often equipped with a variable-speed drive, powers the drive sprocket; the drive sprocket and motor form the drive assembly. An idler assembly (sometimes called an idler stationer tension station) is located at the end of the conveyor’s return line. The idler assembly consists of a housing enclosing an idler sprocket or other rotating mechanism and, in some cases, a chain-tensioning device. A conveyor with a complex loop arrangement can have a combination of several 90-degree turn assemblies (also called turn stations) and less-than-90-degree elbows, which allow the chain to turn and bend with minimal friction. Each turn assembly contains a sprocket or other rotating mechanism, which can be a powered or idler mechanism, the elbows don’t require a rotating mechanism. Brushes or other devices can be located at the drive assembly and at various points inside the conveyor housing to clean material off the chain-and-disc assembly and prevent carry back in the return line.

The conveyor can have one or multiple material inlets and outlets. When it has one inlet, the inlet is located near the idler assembly; additional inlets can be located along the conveying line. When the conveyor has one outlet, the outlet is located at the drive assembly; additional outlets can be located along the conveying line prior to this point.