Company Information

Ask for more detail from the seller

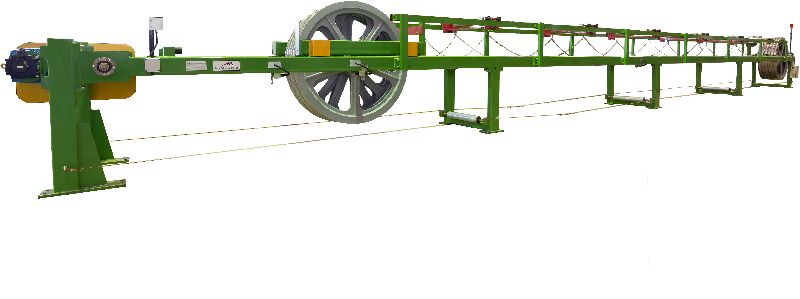

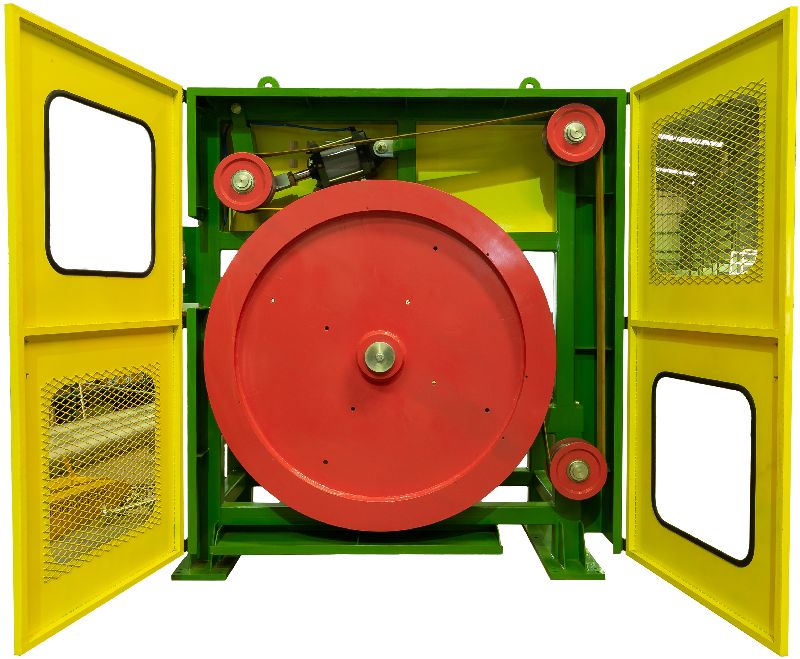

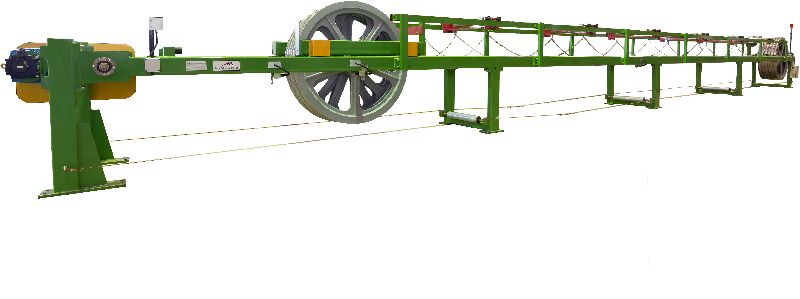

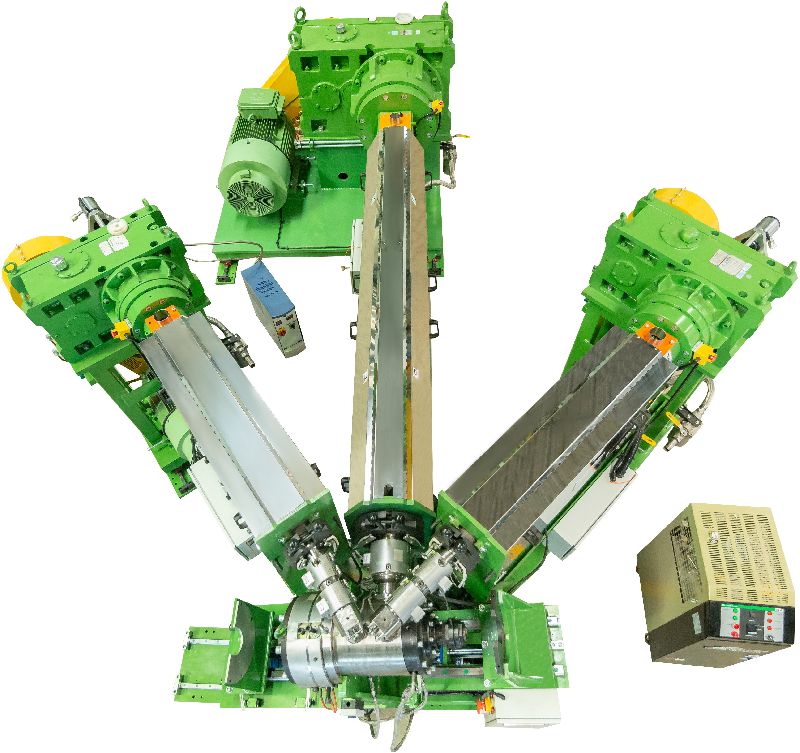

Contact SupplierDescription: The DRY CURE CV is an advancement of Royle’s 1958 Patent of the Catenary Continuous Vulcaniser (CCV) Technology. With 100s of CCVs running all over the world, Royle’s pioneering patent is now universal DRY CURE CV lines are currently manufacturing Cables from 6KV to 220KV.

Royle, remains as the only company that manufacturers CCVs by precisely bending the catenary pipes to the specific design coordinates of the catenary formulae. This manufacturing capability is superior to other methods that use wedges between pipes to approximate the catenary curve, as that alternate method can cause scuffing of cables during the curing process.

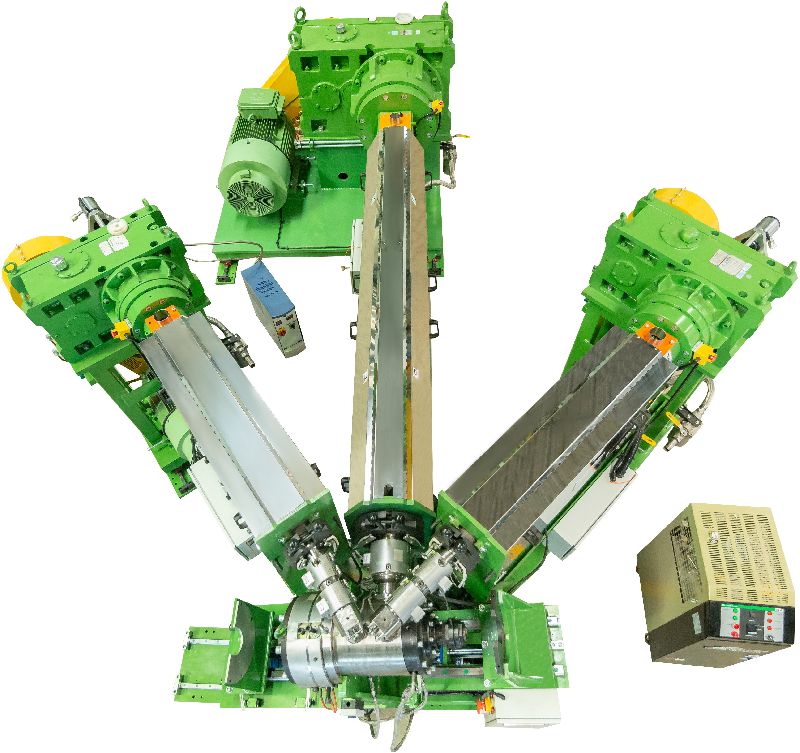

Royle provides lines that can efficiently perform triple extrusion process, precisely applying the inner semiconductor layer, insulation layer, and outer semiconductor layer in a single pass.

The technology edge spreads to different aspects. For instance, the potential scrap during the starting and stopping of the line is controlled by Royle’s process guidance and Royle’s Autoline system in conjunction with Royle’s time-tested Cure-Cool Simulation software, which is yet another proficiency that our customers can benefit from