Company Information

Ask for more detail from the seller

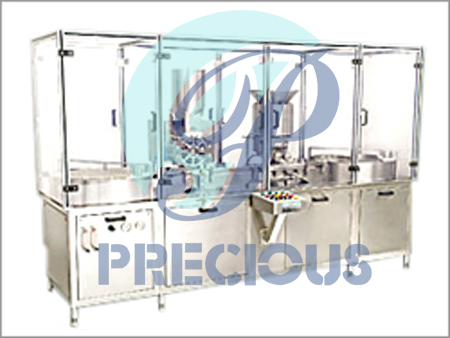

Contact SupplierAutomatic Injectable Powder Filling with Rubber Stoppering is a compact model used for filling Stoppering of Dry Powder Injectable in to vials.

The incoming dry container sterilized are fed through the Un-scrambler and suitably guided on the moving delrin flat conveyor belt at the required speed of the correct placement below powder wheel.

The sterilized powder is stored in powder hopper is agitated by pair of mechanical agitators for maintaining consistency and uniform bulk density. The powder wheel having eight ports rotates at the pre determined speed below the powder hopper with practically no clearance. Powder wheel consist of Piston in each port and behind the powder wheel vacuum plate is provided there is no clearance between powder wheel and vacuum plate due to back spring pressure. Precise volume of powder is sucked in to the port of powder wheel during vacuum according to the piston length different fill size can be achieved. The excess powder is doctored off by a doctor blade. Doctor blades can be adjusted from outside also without removing powder hopper. When powder wheel indexes further and remain in the port due to the vacuum till it reaches just vertically above the container. The time dose of Compressed air (Nitrogen Gas), sterilized low pressure air sequentially flushes out powder from the port of powder wheel in to the container one by one.

The filled container is immediately separated on the conveyor by vial separator and moves further for Stoppering operation. (Different grooves separator can be used which depends on the container diameter or multiple dosing systems).

The sterilized, siliconised, rubber stoppers stored in the vibrator bowl moves to vibratory bowl and stacked vertically in the rubber stopper chute. The container is hold firmly between pair or timing belt to pickup rubber stopper from exit end of the chute. Further the container is passed between two pressing roller for tight fit fixing of rubber stopper.

MODEL NO. | CPAPFRS-1. | CPAPFRS-2 D. |

Direction | Left To Right. | Left To Right. |

Production Rate | Up to 100 Fills / Min for Single Dose. | Up to 180 fills / Min for Single Dose. |

Fill Capacity | 50 mg to 1.5 grms. Single Dose (with Change Parts) | 50 mg to 1.5 grms. Single Dose (with Change Parts) Fill range depending upon vial opening and bulk density of powder. Under controlled level of Humidity (i.e. 25%) |

Accuracy | ± 1% depending upon consistency and the uniformity of bulk density of Injectable powder Under controlled level of Humidity (i.e.25%) | ± 1% depending upon consistency and the uniformity of bulk density of Injectable powder Under controlled level of Humidity (i.e.25%) |

Electrical Supply | 1.00 HP For Main Drive. | 2.00 HP For Main Drive. |

Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

Height of Conveyor | Adjustable from 800 To 850 MM | Adjustable from 800 To 850 MM |

Vial Diameter | 25 MM To 45 MM MAX. | 25 MM To 45 MM MAX. |

Height | 75 MM MAXIMUM. | 75 MM MAXIMUM. |

Rubber Stopper | 20 MM DIAMETER. | 20 MM DIAMETER. |

Pneumatic Air | Filtered, oil free, sterile low pressure AIR at 2 kg/cm2 (2/3 bar) | Filtered, oil free, sterile low pressure AIR at 4 kg/cm2 (4/6 bar) |

Vacuum line | 20 HG. (Pump will be supplied by CP.) | 20 HG. (Pump will be supplied by CP) |