Company Information

Ask for more detail from the seller

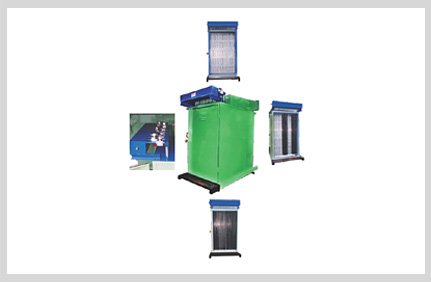

Contact SupplierSalient Features

Application Area

| DIMENSION |

| ||||||

| MODEL | LENGTH | BREATH | HEIGHT | ||||

| SSEC ID / 60 | 1800 | 720 | 2265 | 60 | |||

| SSEC ID / 80 | 1800 | 940 | 2265 | 80 | |||

| SSEC ID / 100 | 1800 | 1160 | 2265 | 100 | |||

| SSEC ID / 120 | 1800 | 1380 | 2265 | 120 | |||