Company Information

Ask for more detail from the seller

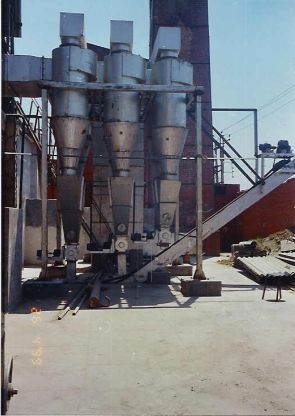

Contact SupplierAll solid fuel fired boilers call for a suitable Air Pollution Control Device due to a high ash content. So Thermodyne provides you the Dust Collectors. During combustion, ash deposed of in several ways,