Company Information

Ask for more detail from the seller

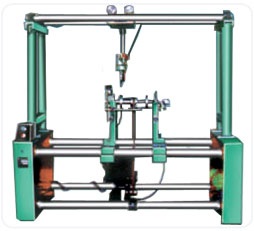

Contact Supplierwith Microprocessor Based Measuring Panel ( Hard Bearing Model - HDCM ) | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

• The balancing speed depends upon selection of the rotor diameter, where drive is to be given and the motor pulley diameter. |

• All the machines above operate on mains supply of 400 to 440 V, 3Ø, 50 cycles. |

• Due to constant R & D, specifications and features are subject to change without notice. The dimensions given above are approximate. |

| Models | Unit | HDCM-10 | HDCM-30 | HDCM-50 | HDCM-100 | HDCM-300 |

| Weight of Rotors | kg | 0.2-10 | 0.3-30 | 0.5-50 | 1-100 | 3-300 |

| Max. wt. on each pedestal | kg | 7.5 | 22.5 | 30 | 75 | 180 |

| Max. diameter of rotor | mm | 250 | 500 | 500 | 800 | 1000 |

| Max. distance between bearings | mm | 300 | 1200 | 1200 | 1200 | 2100 |

| Min. distance between bearings ( drive outside pedestal ) | mm | 20 | 50 | 50 | 50 | 150 |

| Shaft diameter | mm | 5-50 | 5-50 | 5-50 | 15-80 | 20-120 |

| * Balancing speed range ( n ) | RPM | 750-3000 | 500-2000 | 500-2000 | 400-1600 | 300-1500 |

| Power of drive motor | HP | 0.33 | 0.75 | 0.75 | 1.5 | 3 |

| Acceleration capability ( gs2n2 ) | kgm2n2 | 0.29x106 | 0.37x106 | 0.37x106 | 0.88x106 | 3.9x106 |

| Min. Unbalance mass measured | g | 0.01 | 0.1 | 0.1 | 0.1 | 0.1 |

| Max. Unbalance mass measured | kg | 0.4 | 4 | 4 | 4 | 4 |

| Unbalanced reduction ratio | % | 95 | 95 | 95 | 95 | 95 |

| Min. Achievable unbalance per rotor wt. ( For max. rotor wt. ) | gmm / kg or micron. | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |