Listing ID #4637670

Ask for more detail from the seller

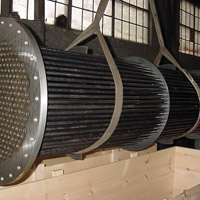

Contact SupplierEcoflux* Corrugated Tube Heat Exchangers (CTHE) use corrugated tubes instead of smooth tubes. The corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology.

Corrugated tube is produced by indenting a plain tube with a spiral pattern. No tube wall thinning takes place & no strength is lost.

Features

Technology:

Corrugated tube is produced by indenting a plain tube with a spiral pattern. This imparts different flow regimes - spiral in the core and eddy's at the periphery.

The helical flow contributes to the situation that the fluid particles are alternatively in the vicinity of the tube wall and then in the main flow. Between the helical impressions, around the circumference of the tube, secondary flow, typically in the form of eddies occur.

The flow regime ensures that the rate of decrease in boundary layer resistance exceeds the rate of increase in pressure loss. In other words high heat transfer coefficients with minimum increase in pressure drop.

Hydrodynamic Thermal Boundary Layer

Increase in heat transfer coefficient brings the temperature of the tube wall closer to the temperature of the bulk fluid on the tube.

The roughness elements need to have a minimum height so as to influence the flow ( Fig. A ) and thus the heat transfer ( Fig. B ). To ensure that the heat transfer is improved by roughness elements, the flow must be influenced within the heat conduction layer.

Advantages:

Corrugated tube shell and tube heat exchangers have many benefits and advantages over comparable smooth tube versions: