Company Information

Ask for more detail from the seller

Contact Supplieredm machining turning parts---plastic mold components and drawings processing

the basic principle of edm is based on the electric corrosion of the spark discharge between the tool and the 【plastic mold components】 (positive and negative electrodes) to remove the excess metal, so as to meet the required processing requirements for the size, shape and surface quality of the parts.

yizedbzt06

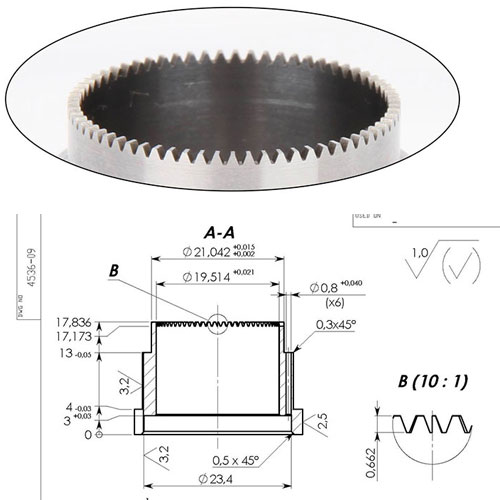

category:edm machining turning parts and drawings

product name:precision plastic mold components

product size: customization

material:japan(skd11.skd61.skh51.s45c)

usa(aisa.d2.h13.p20.m2)

germany(din.2379.2363.2344.2347)

assab(rigor.stavax.impax.elmax.asp23)

hardness:58-60 hrc

grinding precision:0.001mm

electric discharge processing precision:0.002mm

delivery time:7 to 10 production days

classification of process methods

1.edm: the forming tool electrode asdyizebgsw is used for profiling electrical discharge machining.

2.wedm: the method of cutting plastic mold components by metal wire as tool electrode.

3.other types of edm such as edm grinding,asdyizesw edm rotary machining,electric spark grinding and so on.

yize edm department is equipped with twelve edm machines including one set of sodick edm machine and four sets of mitsubishi edm machines. Edm precision within 0.003mm, edm angle yizedbzt07 clearance within r0.015,edm surface roughness within ra0.2 are the technical precision available.