Listing ID #6114124

Company Information

Ask for more detail from the seller

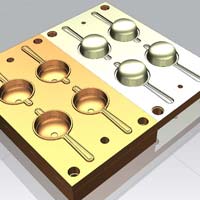

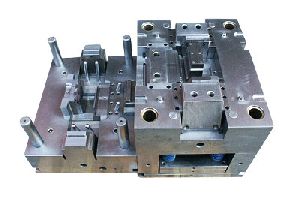

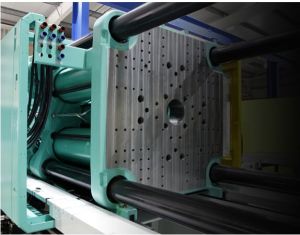

Contact SupplierOur blow molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.

Common Applications

How Does Plastic Blow Molding Work?