Listing ID #4272939

Company Information

Ask for more detail from the seller

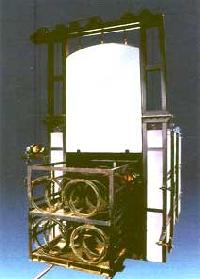

Contact SupplierWe are a well know supplier of Hardening Furnace which has a bogie hearth heavy structure that normalizes and hardens furnace (indirect fired furnace). The furnace is best suited for different industrial metal heat treatment. Our range of furnace has an extractable loading plate which is used for loading and unloading of the furnace.

The hardening furnaces are used for the hardening, the annealing and the preheating of the metal charge before the armouring, under the oxidizing atmosphere especially. The furnaces at the semi-gastight version with retort (see. the datasheet the semi- gastight version of the furnaces), can be used for the heat treatment of the charge below the partially shielding gas. They can be used for preheating of moulds in glass industry.

Description of Hardening Furnace:

Equipment of Hardening Furnace includes:

Benefits: