Listing ID #4417524

Company Information

Ask for more detail from the seller

Contact SupplierApplications

Features

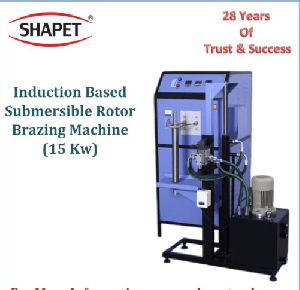

| POWER RANGE | 1-5KW | 05-15KW. | 15-50KW | 50 -200KW |

|---|---|---|---|---|

| FREQUENCY RANGE | 15-400kHz | 15-100 kHz | 15-30kHz | 15 – 30kHz |

| ADAPTATION TO CHANGE LOAD CHARECTERISTICS | YES | YES | YES | YES |

| POWER CONTROL | AUTO | AUTO | AUTO | AUTO |

| LOAD SENSED SELF TUNING | YES | YES | YES | YES |

| SIZE (mm) | W-170 B-495 H-350 |

W-530 B-640 H-1110 |

W-620 B-725 H-1370 |

W-1000 B-1090 H-1675 |

| INPUT POWER RANGE | SINGLE PHASE 230V/50Hz. |

THREE PHASE 440V/50Hz |

THREE PHASE 440V/50Hz |

THREE PHASE 440V/50Hz |