Company Information

Ask for more detail from the seller

Contact SupplierElectrical Safety Audit Services in Chennai, Tamil Nadu, Thermography Testing/Thermal Imaging Testing Service in Chennai.

We are exporter engaged in offering Electrical Safety Audit Services – Thermography Test in Chennai, Tamil Nadu,

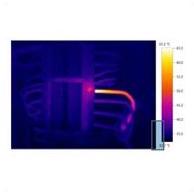

PS Power Controls provides professional Thermography Testing (also known as Infrared Thermal Scanning, IR Thermography, or Thermal Imaging Inspection) as a vital part of our power quality and electrical safety audit services. In modern industrial, commercial, IT, healthcare, and manufacturing environments, undetected hotspots in electrical systems can lead to catastrophic failures, fires, and costly downtime. Thermography testing uses advanced infrared cameras to detect abnormal heat patterns non-invasively, making it an essential predictive maintenance tool.

Why Thermography Testing is Crucial for Electrical Safety and Power Quality

Infrared thermography (IR scanning) captures thermal images that reveal temperature differences invisible to the naked eye. It identifies issues like loose connections, overloaded circuits, faulty components, imbalanced loads, deteriorated insulation, and poor terminations before they escalate.

Factors like aging infrastructure, dust accumulation, corrosion, vibration, or environmental conditions can cause gradual degradation, increasing resistance and heat. Periodic thermal scanning detects these changes early, enabling targeted interventions such as tightening connections, replacing components, or load balancing.

Maintenance personnel can correct the problem before the component fails. Infrared thermography is used to perform inspections on electrical equipment because excess resistance on electrical apparatus indicates electrical faults such as: