Company Information

Ask for more detail from the seller

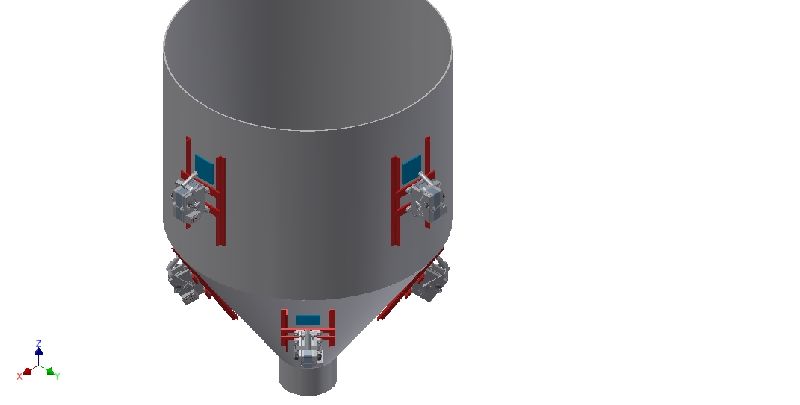

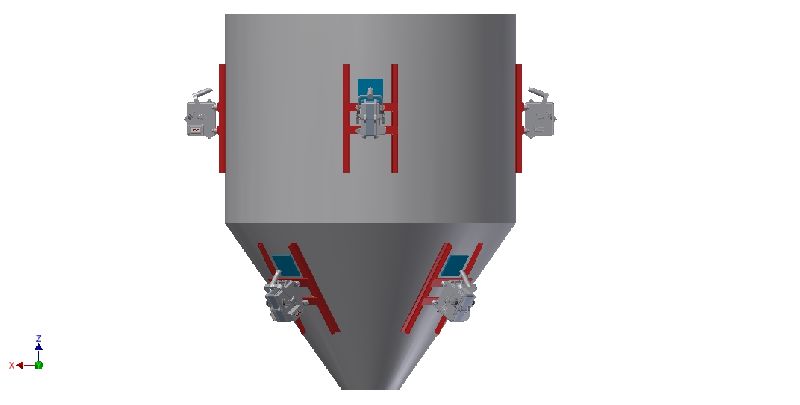

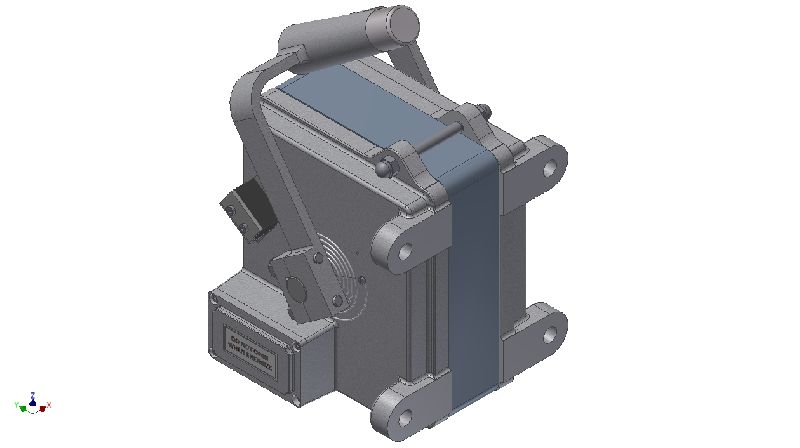

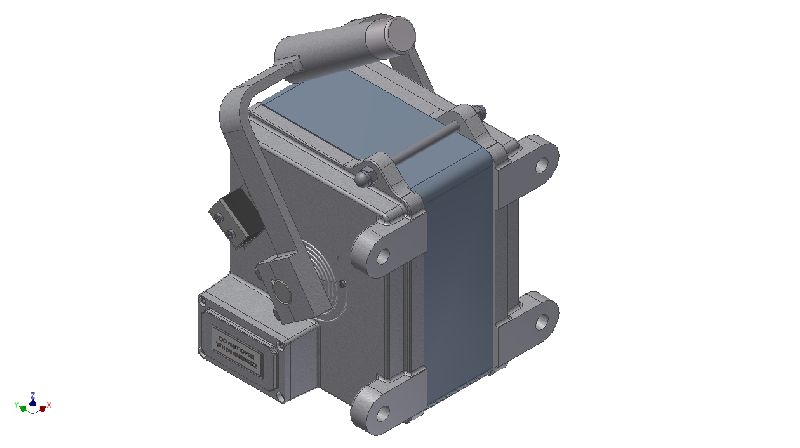

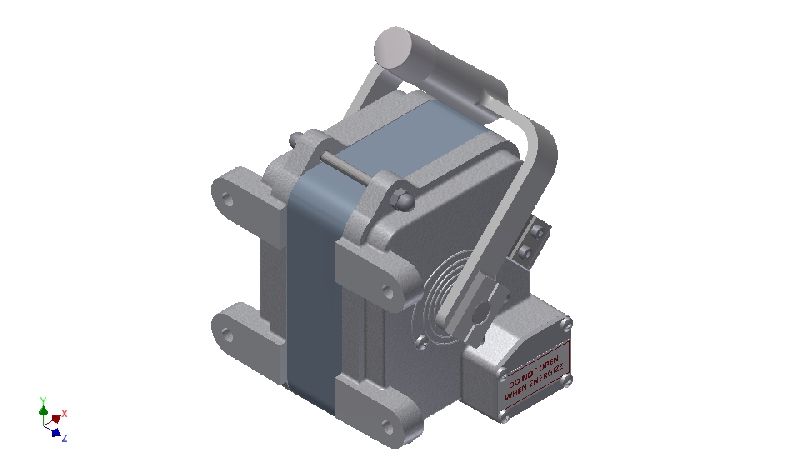

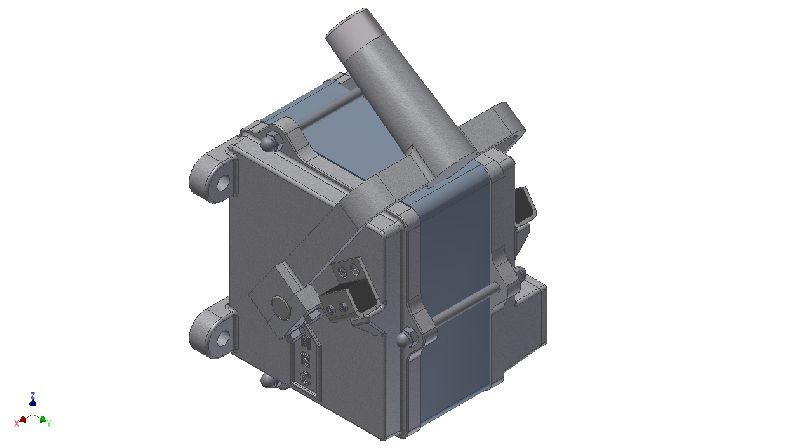

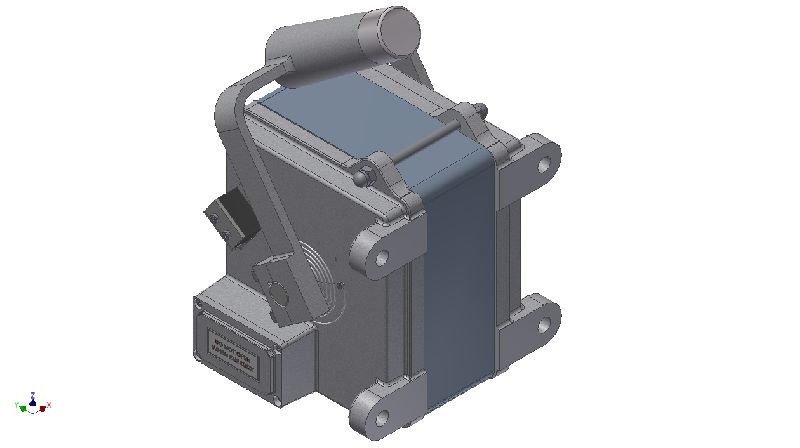

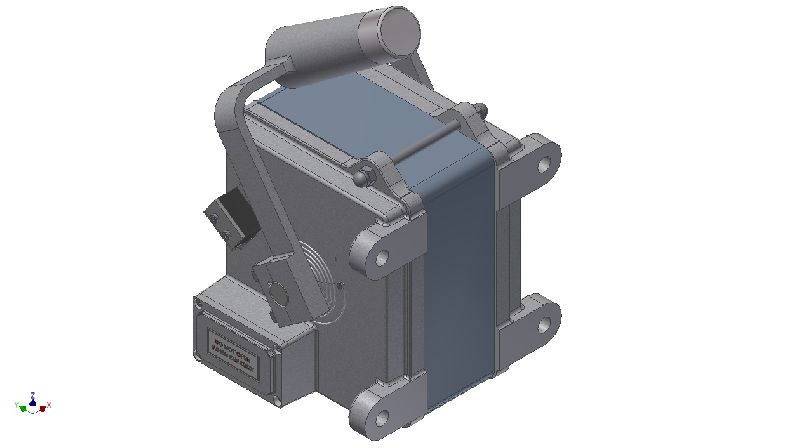

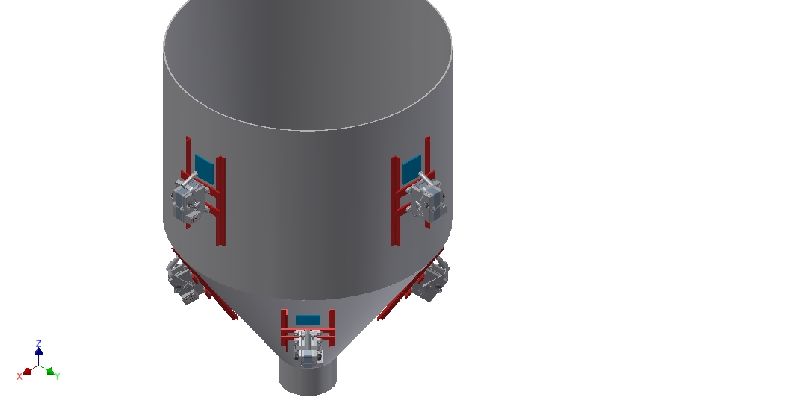

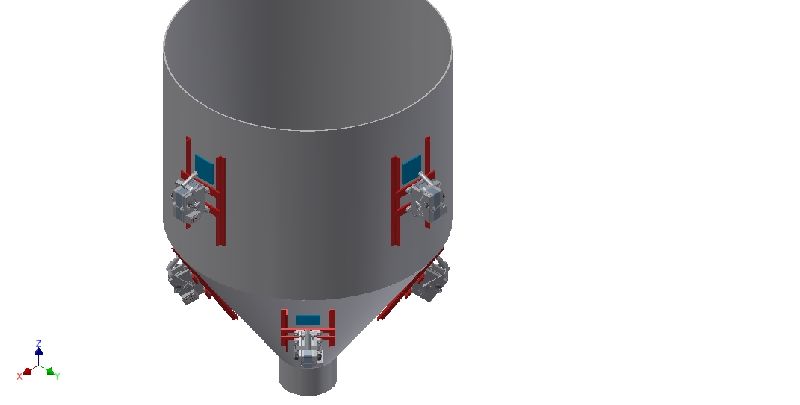

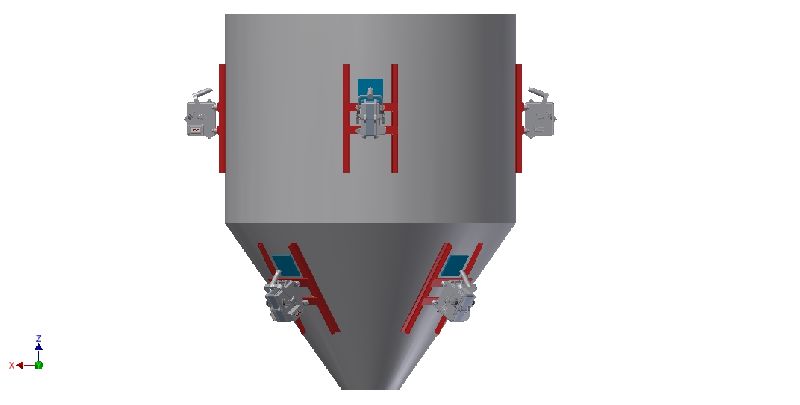

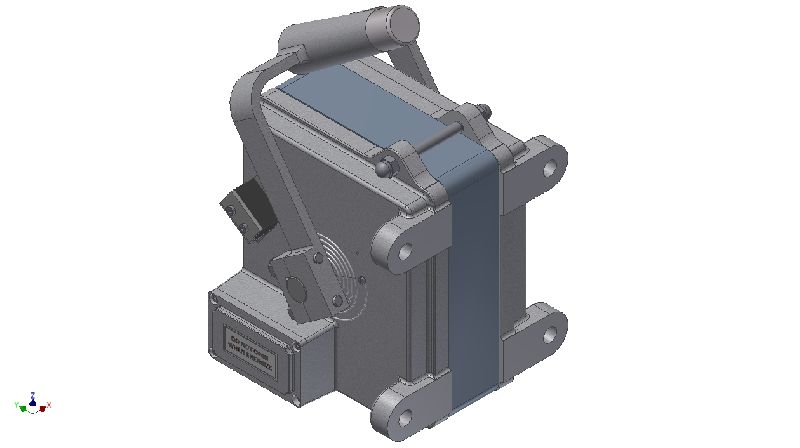

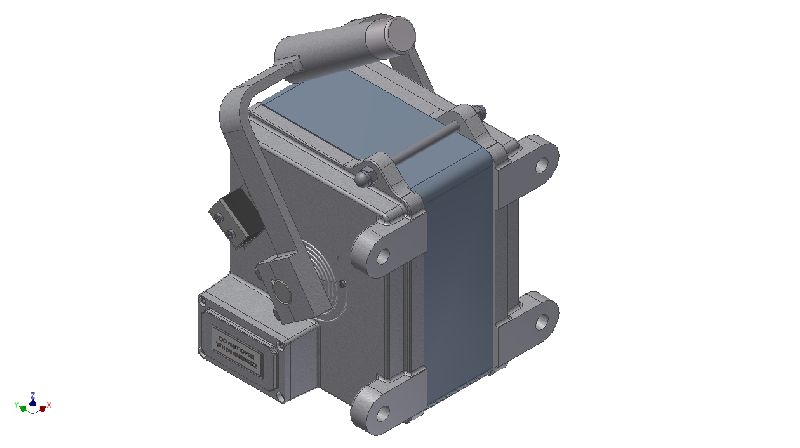

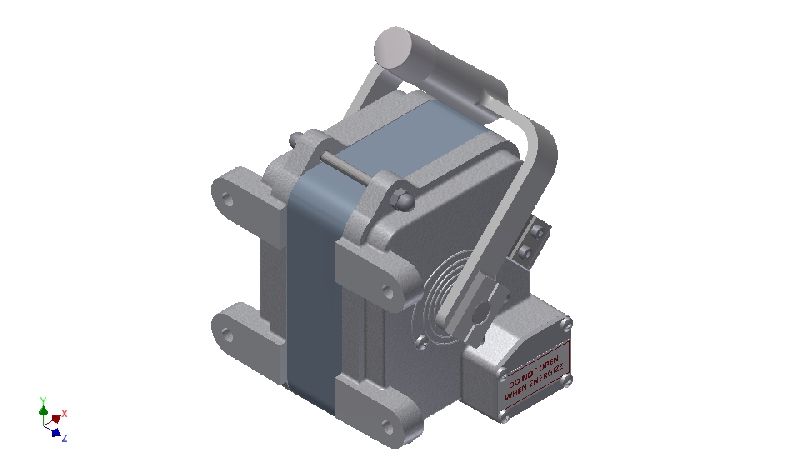

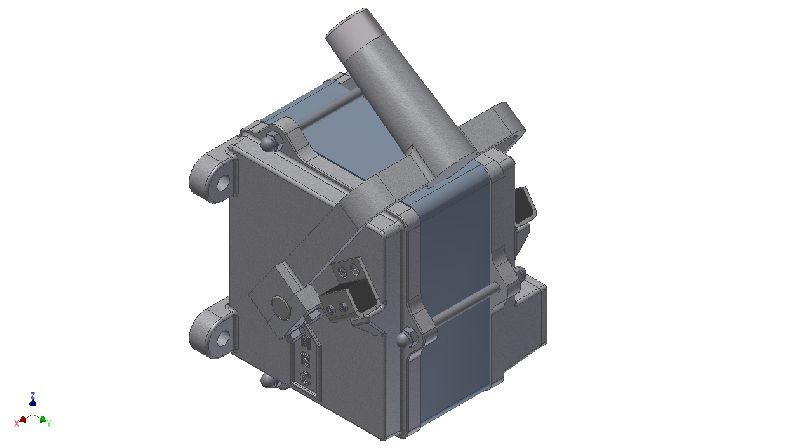

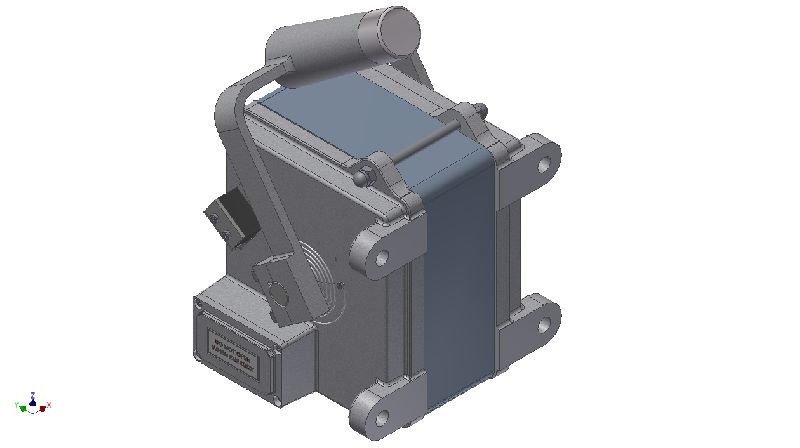

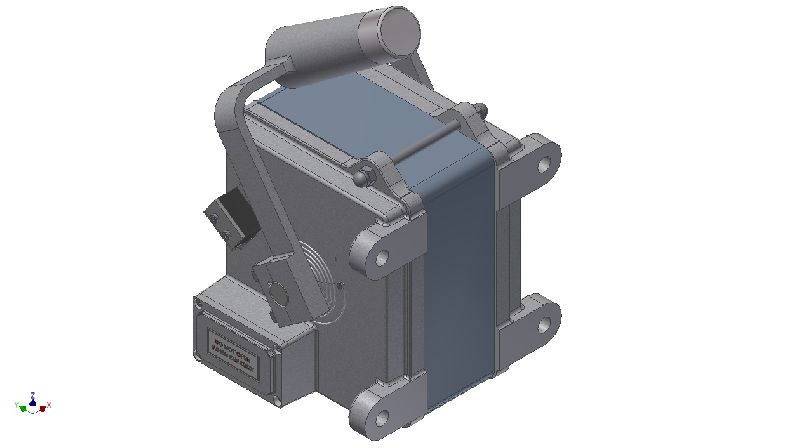

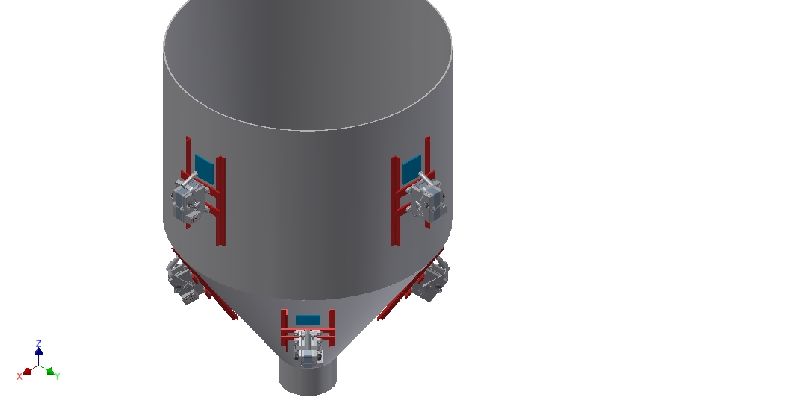

Contact SupplierWe are engaged in the manufacturing of an exclusive range of Electromagnetic Hammer that is known for its performance and sophistication. Our range of Electromagnetic Hammer is engineered from premium quality raw materials and is in high demand in the market. The Electromagnetic Hammer is available in diverse dimensions and offered at economical prices. Electromagnetic Hammer we supply in the market is in high demand both in the national and international market.

Speciality

Components and working

Supplied to

Features

Click here for Technical Details

| Model | Volt | Pulse Current (amp) | Power Consumption @ 10 strokes/min | Mpact Force | Weight (kg) |

|---|---|---|---|---|---|

| NEC - EH - S | 230 VAC | 2 | .001 units/hr. | 2.0 Kgf | 7 kg |

| NEC - EH - 50 | 415 VAC | 4 | .003 units/hr | 3.5 Kgf | 15 kg |

| NEC - EH - 75 | 415 VAC | 6 | .045 units/hr. | 5.5 Kgf | 20 kg |

| NEC - EH - 75B | 415 VAC | 10.5 | .065 units/hr. | 7.0 Kgf | 25 kg |

| NEC - EH - 75 HI | 415 VAC | 30 | .090 units/hr. | 10.5 Kgf | 30 kg |

| Model | Volt | Pulse Current (amp) | Power Consumption @ 10 strokes/min | Mpact Force | Weight (kg) |

|---|---|---|---|---|---|

| NEC - EH - 50 | 415 VAC | 4 | .003 units/hr. | 3.5 Kgf | 15 kg |

| NEC - EH - 75 | 415 VAC | 6 | .045 units/hr. | 5.5 Kgf | 20 kg |

| NEC - EH - 75B | 415 VAC | 10.5 | .065 units/hr. | 7.0 Kgf | 25 kg |