Company Information

Ask for more detail from the seller

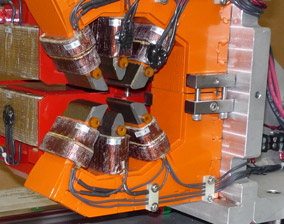

Contact SupplierEverson Tesla is continually on the cutting edge of magnet manufacturing technology, facilitated by our strong background in tooling design, manufacturing engineering, hydraulics, winding component integration and controls - all supported by an integrated manufacturing structure that provides efficient project start-ups and cost-effective results.

Tools used to assist system and component design include:

Commercially available and proprietary 2-D magnet design programs

ANSYS finite element 3-D engineering, magnetic, structural and thermal analysis programs

Autocad computer-aided design program in 2-D and 3-D

Everson Tesla leads in the development of:

Computer-controlled roll forming and winding for fusion and high magnetic field research

Innovative production technology for sheathing Cable-in-Conduit superconductor in 1-km lengths for large magnet designs

Forming the most challenging resistive and superconducting materials into demanding coil configurations to tight tolerances

Use of insulation materials for radiation-resistant application

Advanced techniques in Vacuum Pressure Impregnation and B-stage impregnation schemes

Precision casting and sophisticated impregnation processes

Solid and laminated iron corefabrication and assembly

Resistive conductor forming with direct and indirect cooling

Layer, pancake, strip winding configurations