Company Information

Ask for more detail from the seller

Contact SupplierToroidal inductors and transformers are electronic components, typically consisting of a circular ring-shaped magnetic core of iron powder, ferrite, or other material around which wire is coiled to make an inductor. Toroidal coils are used in a broad range of applications, such as high-frequency coils and transformers.

Toroidal inductors can have higher Q factors and higher inductance than similarly constructed solenoid coils. This is due largely to the smaller number of turns required when the core provides a closed magnetic path. The magnetic flux in a high permeability toroid is largely confined to the core; the confinement reduces the energy that can be absorbed by nearby objects, so toroidal cores offer some self-shielding.

Common Mode Chokes

Design requirements for a common mode choke

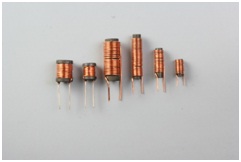

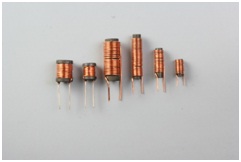

Toroid Inductors

Toroid style common mode chokes are designed to provide the highest common mode impedance over the widest frequency range. These parts are ideal for any application requiring a high DC current bias and are well suited for use in switch-mode power supplies. Common mode chokes are most effective in filtering supply and return conductors with in-phase signals of equal amplitude. Differential mode inductors are available for filtering out-of-phase or uneven amplitude signals.

A Toroidal inductor is an inductor that is designed on a doughnut shaped core. Toroidal inductors offer small size, less leakage inductance and lower electromagnetic interference (EMI).

Design requirements for a Toroidal Inductors:

Typical minimum requirements to be specified for a Toroidal inductor design are:

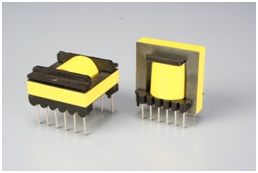

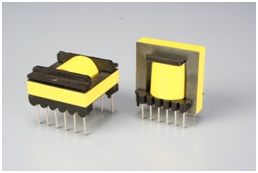

Pulse Transformer

A pulse transformer is a transformer that is optimized for transmitting rectangular electrical pulses--that is, pulses with fast rise and fall times and a relatively constant amplitude.

Principle 8 Operating Principles

The magnetic flux in a typical A.C. transformer core alternates between positive and negative values. The magnetic flux in the typical pulse transformer does not. The typical pulse transformer operates in an “unipolar” mode (flux density may meet but does not cross zero.)

Pulse transformer designs vary widely in terms of power rating, inductance, voltage level (low to high), operating frequency, size, impedance, bandwidth (frequency response), winding capacitance, and other parameters. Designers try to minimize parasitic elements such as leakage inductance and winding capacitance by using winding configurations which optimize the coupling between the windings.