Company Information

Ask for more detail from the seller

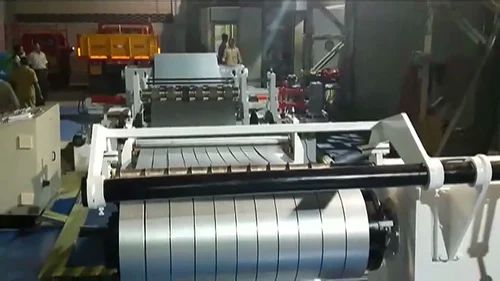

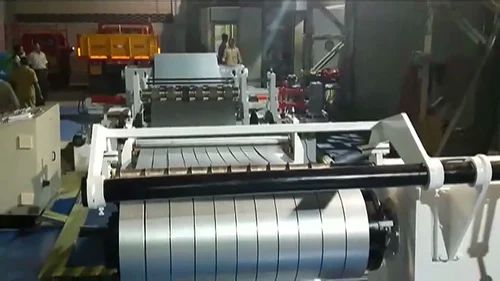

Contact SupplierNirmal offering High Speed tube mill for making ERWIAPUBSIIS and related applications rating maximum up to 12Omi‘min which are based on German and Taiwan Design and technology. Tube mill includes Fully mechanized system with Automatic feeding spiral system with NC cold saw cut of unit and High frequency solid state power saving Welders Tube mill mainly consists of strip preparation, pipe forming, welding, cooling, sizing straightening‘ pipe cut-off unit and pipe take off unit. A forming motor of and a sizing motor and power transmission is done by worm gear boxes drives the whole machine.

The strip first requires leveling and straightening which is done by passing the strip through strip leveler, pinch rolls and guide rolls. After this‘ the strip is passed through various forming rolls where the strips are converted into open seam pipe. Then it reaches the welding unit where the edges of the open seam tube is heated by hf induction generator [or any other welding equipment). Immediately after heating, the edges of the pipe are forged {fused} in the squeezing unit and it takes the shape of complete pipe. After welding, the welding portion is scrapped by bead scrapping unit then the tube is cooled in coolingjacket. For making it exact round the pipe is passed through sizing unit and then through turks head for straightening. After this the tube is cut into required length by a moving cutting machine and pushed to take off table.

| Model | Tube OD (mm) | Wall Thickness (mm) | Line Speed (Mtr/Min) | ||

| Min | Max | Min | Max | ||

| NTPL-50 | 12 | 50.8 | 0.5 | 2.5 | 80 |

| NTPL-76L | 15.88 | 76.2 | 0.7 | 3.2 | 80 |

| NTPL-76H | 15.88 | 76.2 | 0.9 | 4.5 | 80 |

| NTPL-90 | 21.3 | 88.9 | 1.2 | 5.4 | 80 |

| NTPL-100L | 25 | 114.3 | 1.2 | 5 | 80 |

| NTPL-100H | 33 | 114.3 | 1.6 | 6 | 80 |

| NTPL-127 | 38.1 | 127 | 1.6 | 6 | 80 |

| NTPL-150 | 60.3 | 168.3 | 2 | 6 | 60 |

| NTPL-200 | 88.9 | 219.1 | 3 | 8.2 | 50 |