Company Information

Ask for more detail from the seller

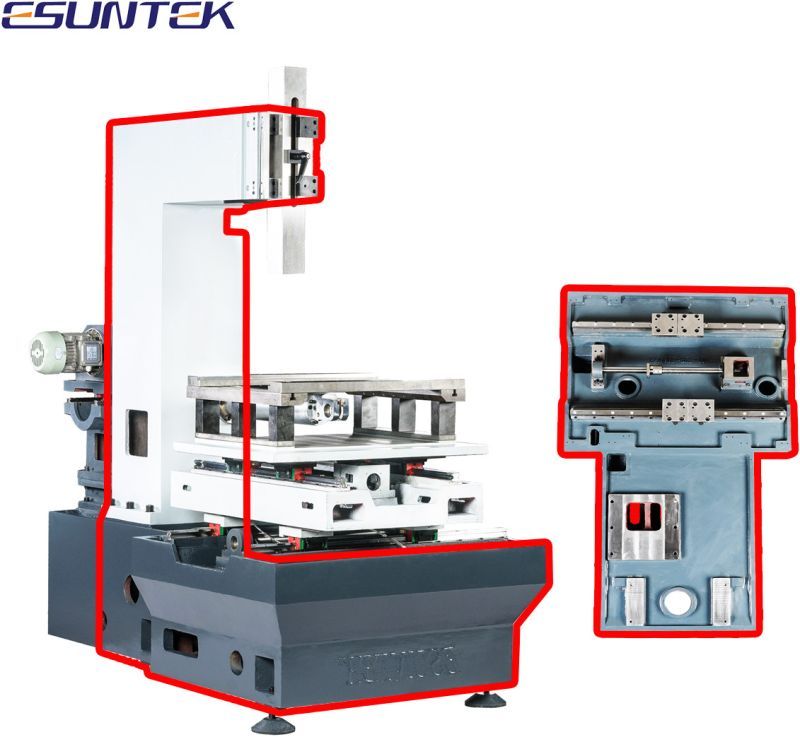

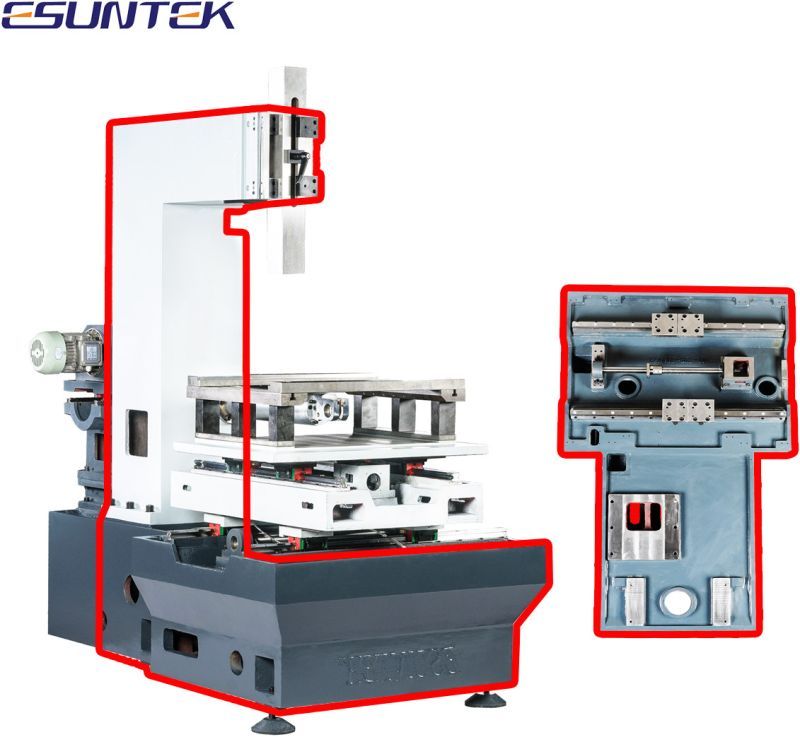

Contact SupplierOur Wire Cutting Machine combines advanced design with high-quality components, specifically designed for precision cutting. With its excellent structural rigidity, precision guideway system, stable wire feeding mechanism, and efficient power supply, it is widely applied in mold manufacturing, mechanical processing, aerospace, and other high-precision fields.

Key Features:

High-Rigidity Structure & Precision Design

The machine base adopts a high-quality Meehanite 250 resin sand cast iron C-type structure, subjected to double high-temperature tempering for excellent toughness and rigidity. Machine accuracy is verified using a laser interferometer before delivery. The servo drive system uses Panasonic (Japan) components for high precision and stability.

Precision Linear Guide System

Equipped with THK (Japan) linear guideways, a double-plane installation structure, and an automatic lubrication system. All guide surfaces are ground in one setup using a professional grinder, ensuring smooth motion and consistent accuracy.

Stable Wire Transport Mechanism

Uses spring constant-tension wire feeding, with wire speed adjustable from 0.5–12.5 m/s. The wire drum (Ø155 mm) can hold up to 400 m of wire. NSK or FAG bearings ensure durability, and maintenance or replacement can be done by general operators without special tools.

High-Efficiency Pulse Power Supply

Independently designed by ESUNTEK, featuring VMOS power transistors with multi-waveform control (rectangular, comb, step wave), achieving high cutting speed, fine surface finish, and low wire loss. Max cutting efficiency: 300 mm²/min; Max current: 10 A.

Advanced CNC System (AutoCut)

Integrated control system using industrial PC, dual-core processor, SSD, and 17” industrial display. Supports AutoCut software with 2D/3D taper cutting, shape machining, DXF import, short-circuit recovery, wire break protection, automatic centering, and multiple cutting cycles.

User-Friendly Handheld Controller

Multi-function hand controller supports axis movement, pump control, wire feeding, and high-frequency switching directly without returning to the control panel. Includes UV-axis locking, high-frequency indicator lights, and collision detection for safe operation.

Smart & Safe Operation Functions

Equipped with intelligent power monitoring (over/under voltage, phase, load, and pump protection), auto power-off after machining, intelligent work light control, molybdenum wire collision alarm, and color light status indication.

Intelligent Software & Diagnostic System

Features automatic fault diagnosis, machining log recording, and open databases (expert + customer). The CAM software also supports automatic programming, simulation, and cutting cost/time estimation.

Convenient Maintenance & Environmental Protection

Centralized lubrication with oil level alarm, sealed guide protection, and four-stage coolant filtration (0.01 mm precision). The machine uses eco-friendly, odor-free cutting fluid and supports clean, splash-free operation.