Company Information

Ask for more detail from the seller

Contact SupplierOur Wire Cutting Machine is designed with advanced electrical discharge machining (EDM) technology for precision processing, widely used in mold manufacturing, mechanical processing, and high-precision industries such as aerospace. Through innovative design and high-quality components, this machine offers exceptional cutting accuracy, stability, and efficiency, making it the ideal choice for your precision machining needs.

Key Features:

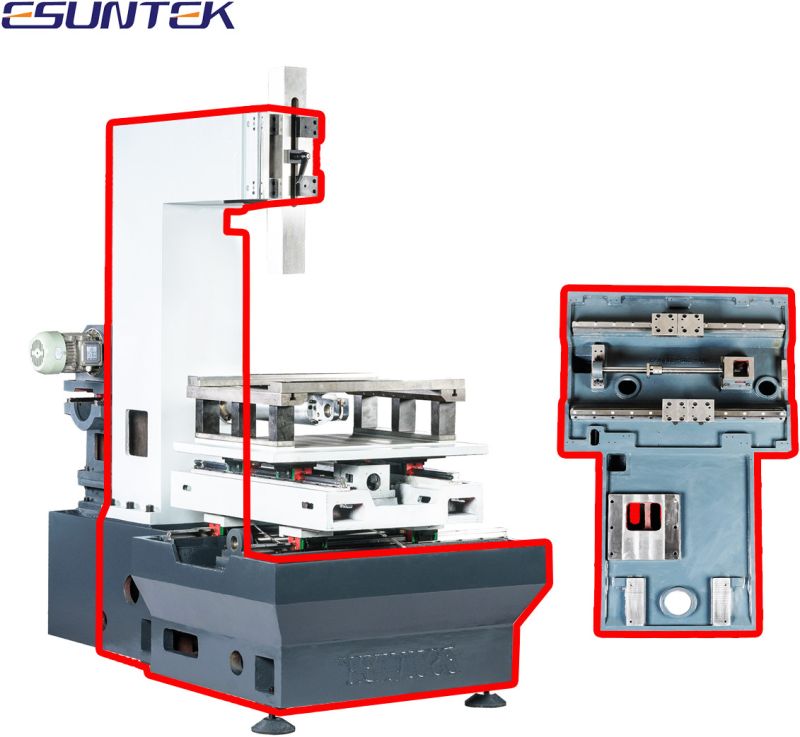

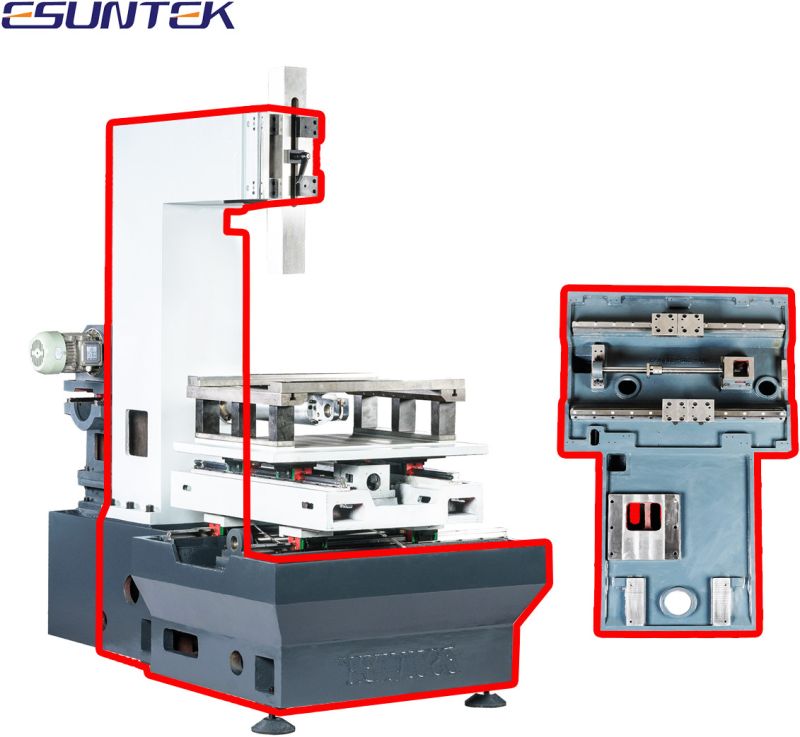

High-Rigidity Structure and Precision Design

The machine bed adopts a C-type structure, made of high-quality Meehanite 250 resin sand cast iron and subjected to secondary high-temperature tempering, providing excellent toughness and overall rigidity. Before leaving the factory, the machine undergoes laser interferometer testing to ensure motion accuracy. The servo drive system uses SIGRINER servo drives, offering stable performance and precise control.

High-Precision Guideway System

Equipped with a dual-plane installation structure and an automatic lubrication system, the guideways are finished in a single pass on a professional grinding machine to ensure smooth motion in all directions, high positioning accuracy, and consistent movement precision.

Stable Wire Feeding Mechanism

Features a spring-loaded constant tension wire feed mechanism with stepless speed adjustment from 0.5 to 12.5 m/s. The wire spool diameter is 155 mm, holding approximately 400 meters of molybdenum wire. Guide wheels and bearings are sourced from NSK or FAG, ensuring long service life and high precision. Routine replacement and maintenance can be performed by general operators.

High-Efficiency Pulse Power System

Developed in-house by Eyang, the VMOS FET pulse power supply supports multiple waveform controls including rectangular, comb, and step waveforms, offering fast cutting speeds, excellent surface finish, and minimal wire consumption. Maximum machining current is 10A, with a maximum processing efficiency of 300 mm²/min. The power supply has a stable structure requiring no special maintenance, and a voltage stabilizer is optionally available.

Advanced CNC System (AutoCut)

The CNC system is industrial computer-controlled, featuring a dual-core high-speed processor, SSD solid-state drive, and a 17-inch industrial LCD. It integrates AutoCut programming software, supporting 2D planar, 3D irregular, taper machining, DXF import, power-off memory, short-circuit recovery, automatic centering, and automatic programming functions.

User-Friendly Hand Control Box

The multifunctional hand control box allows direct control of all axes, water pump, wire feed, and high-frequency switch without returning to the control cabinet. Features include UV-axis locking, high-frequency status indicators, and collision protection, providing intuitive, safe, and reliable operation.

Intelligent and Safety Protection Features

Equipped with an intelligent power monitoring system, providing over-voltage, under-voltage, phase loss, and overload protection. Other intelligent functions include automatic shutdown after machining, smart work light control, molybdenum wire contact alarms, and tri-color indicator lights for processing/fault status, ensuring energy efficiency and safety.

Smart Software and Self-Diagnostic System

The system supports automatic fault diagnosis, maintenance log recording, and contains expert and customer databases for storing machining parameters for various materials. CAM software supports automatic programming, path simulation, and machining time and cost calculation.

Convenient Maintenance and Environmentally Friendly Design

Centralized lubrication system with oil level alarms; fully sealed protection for all coordinate guideways. The cutting fluid system uses four-stage filtration (0.01 mm precision), is odor-free, splash-free, easy to clean, and simple to maintain.