Company Information

Ask for more detail from the seller

Contact Supplier1. Use imported optical components, good beam quality, high efficiency of Electro-optic conversion.

2.High ratio between quantity and price, good reliability, long-term stability, fast speed, high efficiency, good economic returns, kerf small, cutting surface smooth.

3. High cutting precision, can meet all requirements of sheet metal processing technology.

4. Focal length automatic follow with cutting head, even if the material surface roughness and also can ensure cutting quality. kerf smooth, perfect, no need clean.

5. Low operation cost, all material can be cut by air only (if need faster cutting speed, using oxygen.)

6. Collecting trailer with wheel, lightweight design, easy to clean material.

7. Powerful smoking device, solve question of metal processing dust and bad environment.

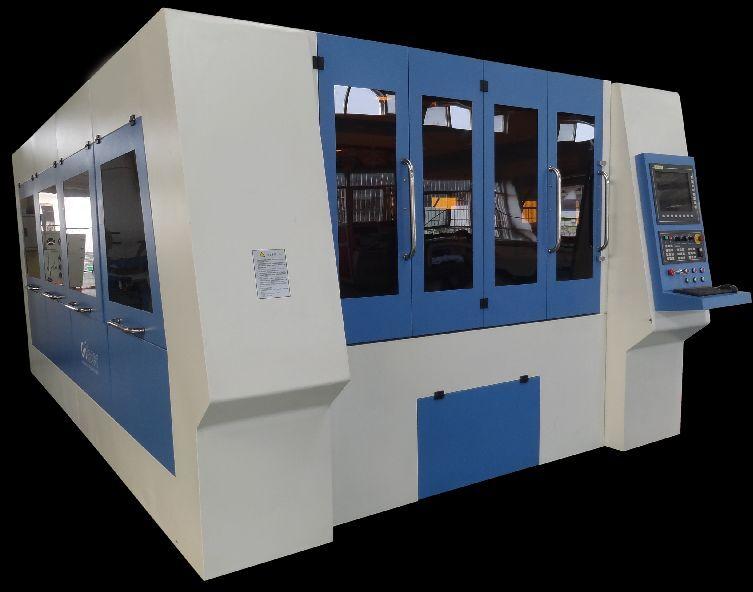

8. Use Gantry mechanism, compact structure, no need take up large area.

9. Imported linear guide rail, Panasonic servo drive, precision gear and rack, and let whole machine work perfect.

10. All screw and guide rail and other motor with auxiliary lubrication system together, use centralized supply lubrication way, effectively ensure lifetime and working precision on each motor.

Widely used for metalsheet processing, advertising trademark, advertising character, high/low voltage electrical cabinet, mechanism parts, kitchenware, cars, mechanical, metal craftwork, saw blade, electronic parts, eyeglasses, spring, circuit board, kettle, medical microelectronics, hard ware, knives tool, measurement, instrument, etc.

Applicable MaterialStainless steel, carbon steel, alloy steel, spring steel, aluminum, aluminum alloy, galvanized sheet, cincalumzalutite, pickling plate, copper, silver, gold, titanium and other metal sheet, pipes and tubes.