Company Information

Ask for more detail from the seller

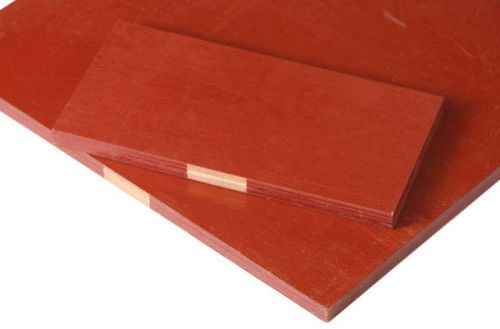

Contact SupplierOur Film Faced Shuttering Plywood is compact and is made of toughened structural plywood. Film Faced Shuttering Plywood that we offer is highly durable as superior film faced densified shuttering Ply is used to make it. Strength factor of our Film Faced Shuttering Plywood make these withstand heavy load of concrete or the vibrations caused due to its pouring. This technique for manufacturing Film Faced Shuttering Plywood is known as 'Heating-cooling Cycle' process.

Our Film Faced Shuttering Plywood is made from selected hardwood veneers, BWP grade of phenol formaldehyde resin that conforms to IS 848:1974. Film Faced Shuttering Plywood, provided by us, can be used for bonding permanent preservative treatment in a vacuum pressure impregnation plant. All this makes our Film Faced Shuttering Plywood resistant to termites and micro-organisms.

Highlights