Listing ID #4922775

Company Information

Ask for more detail from the seller

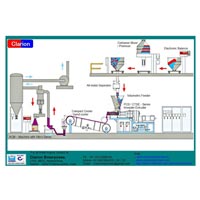

Contact SupplierThe Coating Unit provides strength to the filter paper media by bonding it with resin and providing corrugations over it. In the Coating Unit, the filter media is processed and fed gradually through following four stations:

Unwinding and Coating Station

Unwinding station houses 02(two) numbers of loading/un-loading shaft to hold paper reels

• Motion of the un-loading shafts controlled through mechanical clutch system.

• Un-wound filter paper passes through a series of Hard-Chrome Plated Rollers (driven through chain-sprocket synchronized drive) before passing through Chemical Coating Tank (M.O.C-Stainless Steel).

• The filter paper gets coated when it passes through a series of Tension Rollers (rubberized) and kisses over a Phenol Resin Coating Roller (dipped in the coating tank).

• The motion of the Coating Roller is controlled with AC motor and Variable Frequency Drive.

• Resin & PVA Methanol Mixing Drums ( 02 numbers of 200 litres capacity) are provided along with gear motor drive.

Station-2) Drum type Paper Drying Station

• Coated paper gets dried-up after it passes through a series of heated drums.

• Diameter of Drier Drum = 500mm

• Width of Paper Drying Drum = 1000 / 1250 / 1600mm / Custom Made

• Drums heated through electrical heater coils.

• System provided with Digital Temperature Controller and ‘Auto-Cut-Off’ system.

• The external surfaces of the drums are hard chrome plated.

Station-3) Paper Corrugation and Marking Station

• The dried paper gets corrugated after it passes through a set of Corrugation Rollers.

• Diameter of Corrugation Rollers = 250mm

• Width of the Paper Corrugating Rollers = 1000 / 1250 / 1600mm / Custom Made.

• Corrugated Paper gets marked on the coated side through Line Marking Reels dipped in an Ink Tray (M.O.C.-Stainless Steel).

• Motion of the Marking Reels controlled through mechanical clutch system.

Station-4) Paper (coated & corrugated) Re-winding Station

• Coated paper is re-winded on a single shaft Re-winding Station.

• Width of Re-winding Unit = 1000 / 1250 / 1600mm / Custom Made.

• Motion of the Re-winding shaft is controlled through mechanical clutch system.

• Motion is provide with AC motor with Variable Frequency synchronized drive.