Company Information

Ask for more detail from the seller

Contact SupplierVarious devices are available to measure the fluid flow rate. Majority of these devices use the Bernoulli’s theorem which states that the sum of pressure head, velocity head and the potential head is constant along a stream line for a steady, in viscid and incompressible flow of fluid. Measurement of fluid flow rate is important to the students of mechanical, chemical, civil and several other branches of engineering.

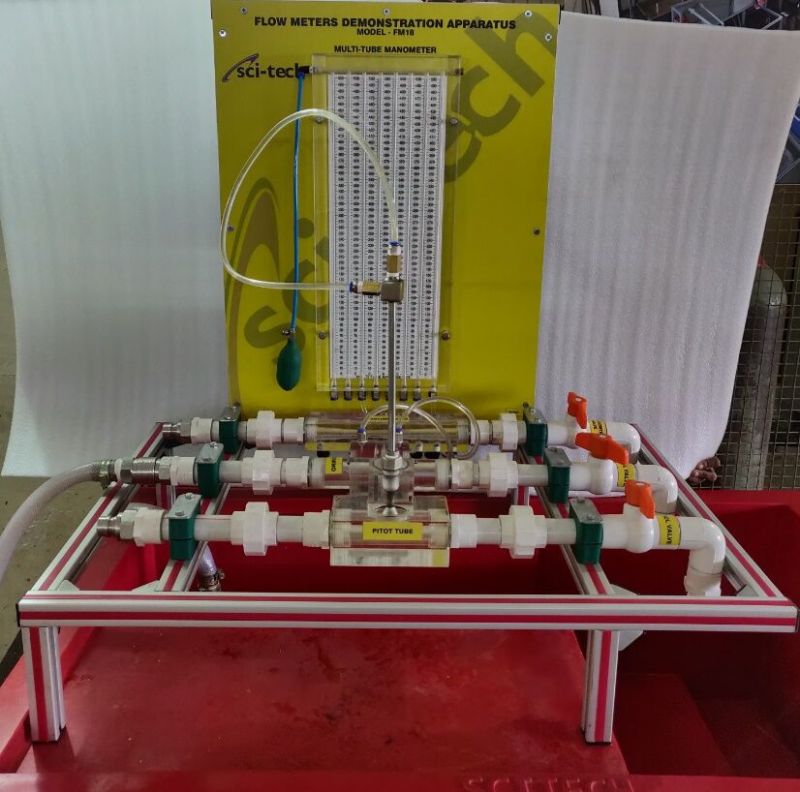

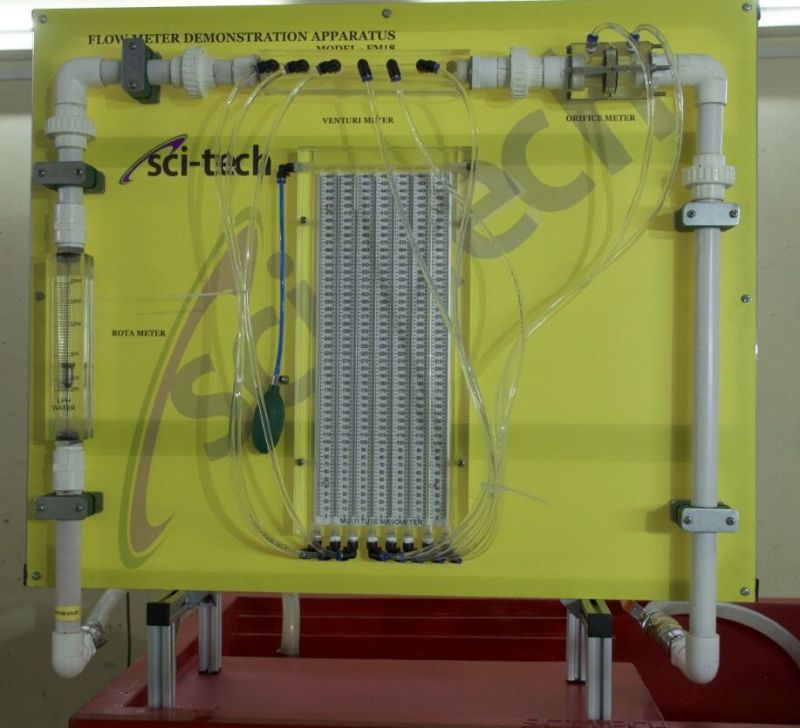

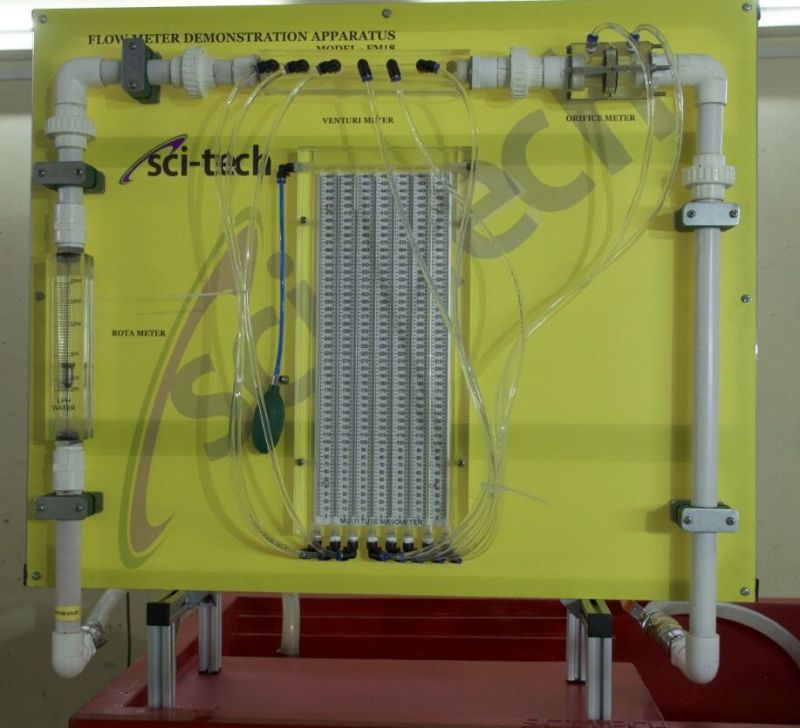

The Sci-tech Flow Meter Demonstration Apparatus Model FM 18 is a mobile bench top unit and has been designed to demonstrate the working of the venture meter, orifice plate and the turbine flow meter. The apparatus consists of a piping network with flow meters located suitably and instrumented with static pressure taps. Provision is made to calibrate and determine the co-efficient of discharge of venture meter and orifice plate. The turbine flow meter is used as a reference. The flow meters are calibrated by static pressure measurements using manometers and actual flow measurements using graduated measuring tank of the hydraulic bench. Wall pressure tapings are provided along the converging and diverging portions of the venture-meter to measure the static pressure distribution. Multi-tube manometer having a manifold with an air bleed valve is supplied to make static pressure measurements. The manometer is pressurized by a hand pump.

Water is supplied by a hose connection to the inlet and flow rate is varied by a valve at the outlet. The complete unit is manufactured from corrosion resistant materials. The FM100 Hydraulic Bench or any other standard hydraulic bench models can be used to supply water.

Specifications:

1. Piping system, 25mm nominal bore, and stainless steel.

2. Venturi meter, transparent, made of clear Acrylic and having convergent and divergent portions, throat diameter: 15mm, maximum diameter: 31.75mm, upstream taper: 210, downstream taper: 140. No. of static pressure taps: 7.

3. Orifice plate, 20mm nominal diameter.

4. Turbine flow meter, 2 - 20 liters/min, max. flow rate.

5. Multi-tube manometer, 0-440 mm water column, No. of tubes: 8 with hand pump.

Options:

1. Other types of water flow measuring devices such as (a) Sudden Enlargement, (b) Elbow (c) Variable Area Rotameter (d) Nozzle and (e) Pitot-tube with necessary pressure instrumentation can be included in the apparatus to suit the requirements of the user on request.

Experiments:

1. Familiarization with static pressure measurements.

2. Familiarization with flow measurement techniques.

3. Determination of co-efficient of discharge of orifice plate.

4. Determination of co-efficient of discharge of venturimeter.

5. Demonstration of continuity equation.

6. Demonstration of Bernoulli’s theorem.

7. Study of static pressure variation along the venturi at different flow rates.

8. Study of working and calibration of turbine flow meter.

Measurements:

1. Static pressures along the venturi meter.

2. Static pressures across orifice plate.

3. Flow rate using turbine flow meter.

4. Actual volume flow rate using Hydraulic Bench or graduated tank.