Company Information

Ask for more detail from the seller

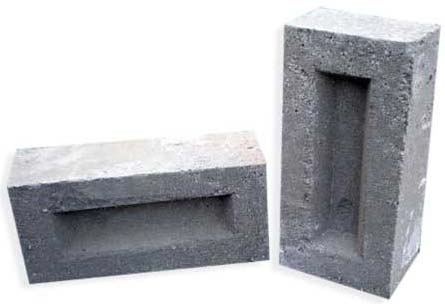

Contact SupplierOwing to our timeliness and hassle free deliveries, we have become the primary choice of the buyers. Owing to immense experience in this domain, we became efficient in providing quality Fly Ash Bricks.

Additional Information

Details

Market Demand

The important compositions of fly ash bricks are as follows:

Future Scope

The highlights of the notification was-

Availability of fly ash for brick making

Specifications for use of ash based products

| Material | Mass |

| Fly ash | 45% |

| Sand/stone dust | 40% |

| Lime sludge | 10% |

| Gypsum | 5% |

| Total formula of material | 100% |

Note : Fly ash bricks are lighter than clay bricks.