Listing ID #6266363

Company Information

Ask for more detail from the seller

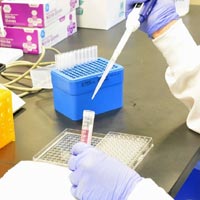

Contact SupplierGrain quality is important for farmers, food producers and, ultimately, consumers. What Should You Test in Grain? Key things to test for in grain include: Moisture, Protein, Specific weight, Mycotoxins, Oil content, Falling number. These various elements in grain will have an impact on its quality, its marketability and its overall value as a product. Moisture content is a major concern. It affects the sale weight of grain and determines whether it can be stored in the long term. Protein is important because food manufacturers and processors will be looking for a specific quality of grain for their products. If a farmer's grain yield fails to match these requirements, they can find their crop rejected or fetching lower prices. The specific weight is a standard, widely understood and accepted measure of grain quality. It is an indicator of the density of grain, and as with protein, producers and millers will have specific weight requirements for the grains they buy. Testing for nitrogen in some grains may be necessary as levels that are too high can lead to a lower specific weight. Testing for mycotoxins is vital, as these naturally occurring toxins can impact crop production, contaminating crops during harvesting, drying and storage. Plus, they pose a risk further up the food chain, if animals eat contaminated feed. Oil content is an essential parameter for various seed crops, including oilseed, including testing the purity of oil. The falling number (FN) test measures alpha-amylase (AA) enzyme activity and levels. Levels of AA activity can determine whether specific grains are suitable for different baked products. This is the original method for testing the suitability of wheat for bread-making. How Should You Inspect Grain for Quality Analysis? There are various inspection methods and tools for monitoring grain quality. Modern grain inspection systems use innovative magnification technology.

CDG inspection systems provide magnification up to 320 times, with multi-viewer options and high-definition live imaging. This enables close-up viewing and assessment of crops for seed or grain quality. Inspection systems can help detect contaminants and identify sprouted or damaged grains. Grain quality testing and analysis come in various forms, using different methods and technologies. These methods are ideal for testing at different parts of the production process: Growing, Harvesting, Storage, Distribution, Food production. Grain Inspections, testing and Audits, CDG is a world-leading third-party inspection company. With a wealth of experience, we ensure fast, quality and reliable testing of grain, wheat, soybean, corn and rice and much more. We use state of the art testing methods and in-house industry experts to provide an extensive range of premium services. Grain Inspection Services, our grain inspections are bespoke based on the different production status of the goods, preventing any risks and delays. This gives ample time for results of quality testing so that your goods can meet with purchase orders. Grain Supplier Audits, our onsite factory audits will assist in developing a deeper understanding of your needs. Giving valuable insight to which suppliers fit best to achieve your business objectives. We also evaluate suppliers based on the criteria which are required.